BESTEK-Engineering LLC-食品加工设备的制造商和供应商

BESTEC-Engineering LLC的任务是开发和实施食品行业最高质量的先进集成技术解决方案。

我们为食品和加工企业制造,供应,组装和调试设备:

肉类罐头生产线(罐头),罐头设备,果蔬加工线,果汁生产线,鱼类加工线,肉类加工线,

乳品设备,黄油生产线,包装设备,黄油包装,填充和包装设备,切面包和包装线等。

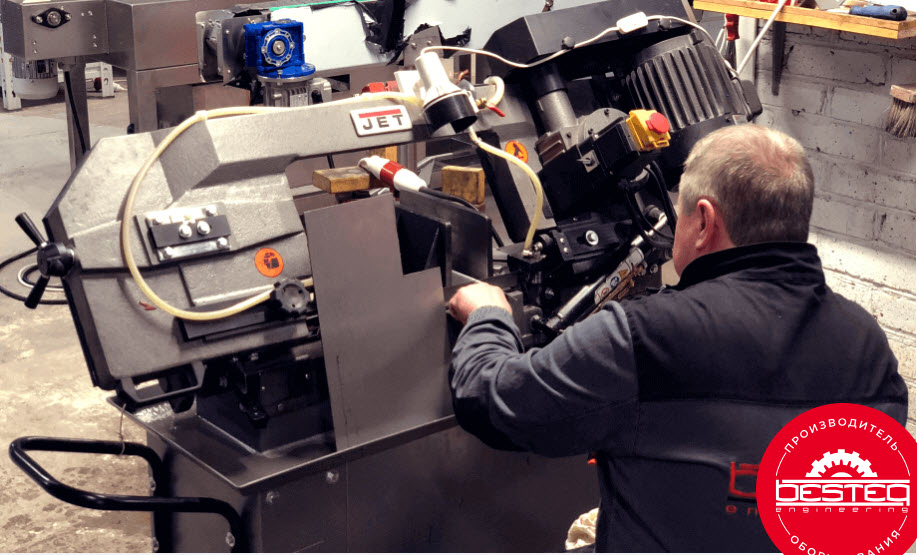

自己生产

各种复杂程度的个性化设计解决方案。由于三重控制和设计文档的协调,保证了产品的质量。

我们自己的生产基地,设计办公室的存在排除了中间贸易利润,从而将设备成本降低了60%!

没有其他公司会为您提供这样的有利条件。

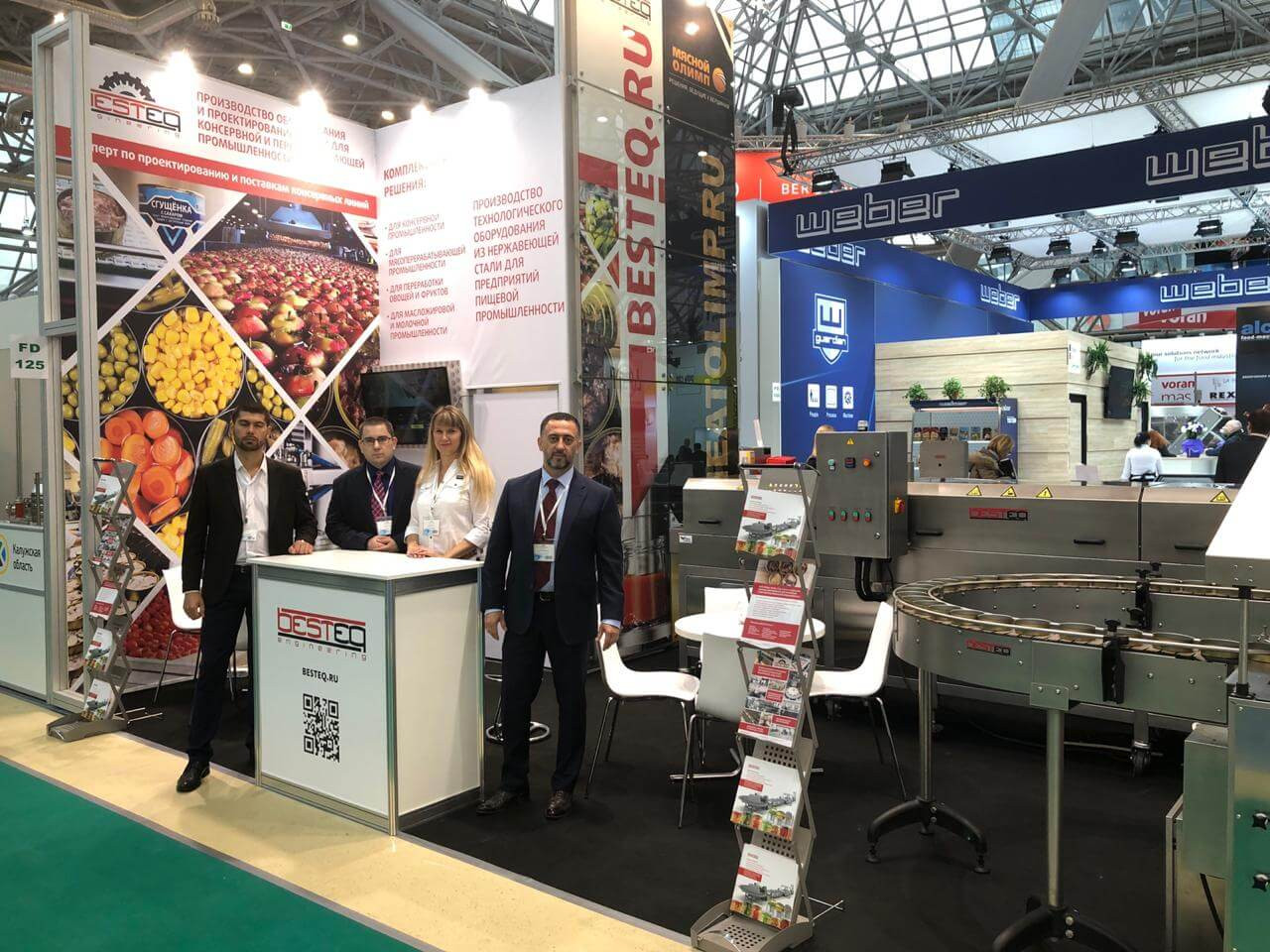

2018年,该公司被俄罗斯联邦农业部认可为进口替代产品的领导者,并在莫斯科的Agroprodmash 2018展览会上获得了“关于进口替代产品的成就”提名的文凭。