BESTEK-Engineering LLC - Hersteller und Lieferant von Geräten für die Lebensmittelverarbeitung

Die Mission von BESTEC-Engineering LLC ist die Entwicklung und Implementierung fortschrittlicher integrierter technischer Lösungen von höchster Qualität für die Lebensmittelindustrie.

Wir fertigen, liefern, montieren und kommissionieren Anlagen für Lebensmittel- und Verarbeitungsunternehmen:

Fleischkonservenproduktionslinien (Fleischkonserven), Konservenausrüstungen, Obst- und Gemüseverarbeitungslinien, Saftproduktionslinien, Fischverarbeitungslinien, Fleischverarbeitungslinien,

Molkereiausrüstung, Butterproduktionslinien, Ausrüstung zum Abfüllen, Butterverpacken, Abfüll- und Verpackungsanlagen, Brotschneid- und Verpackungslinien usw.

Eigene Produktion

Individuelle Designlösungen in jeder Komplexität. Dank der dreifachen Kontrolle und Koordination der Konstruktionsdokumentation ist die Qualität der Produkte garantiert.

Die Präsenz unserer eigenen Produktionsbasis, des Konstruktionsbüros, schließt Zwischenhandelsspannen aus und senkt somit die Kosten für die Ausrüstung auf 60%!

Kein anderes Unternehmen bietet Ihnen so günstige Konditionen.

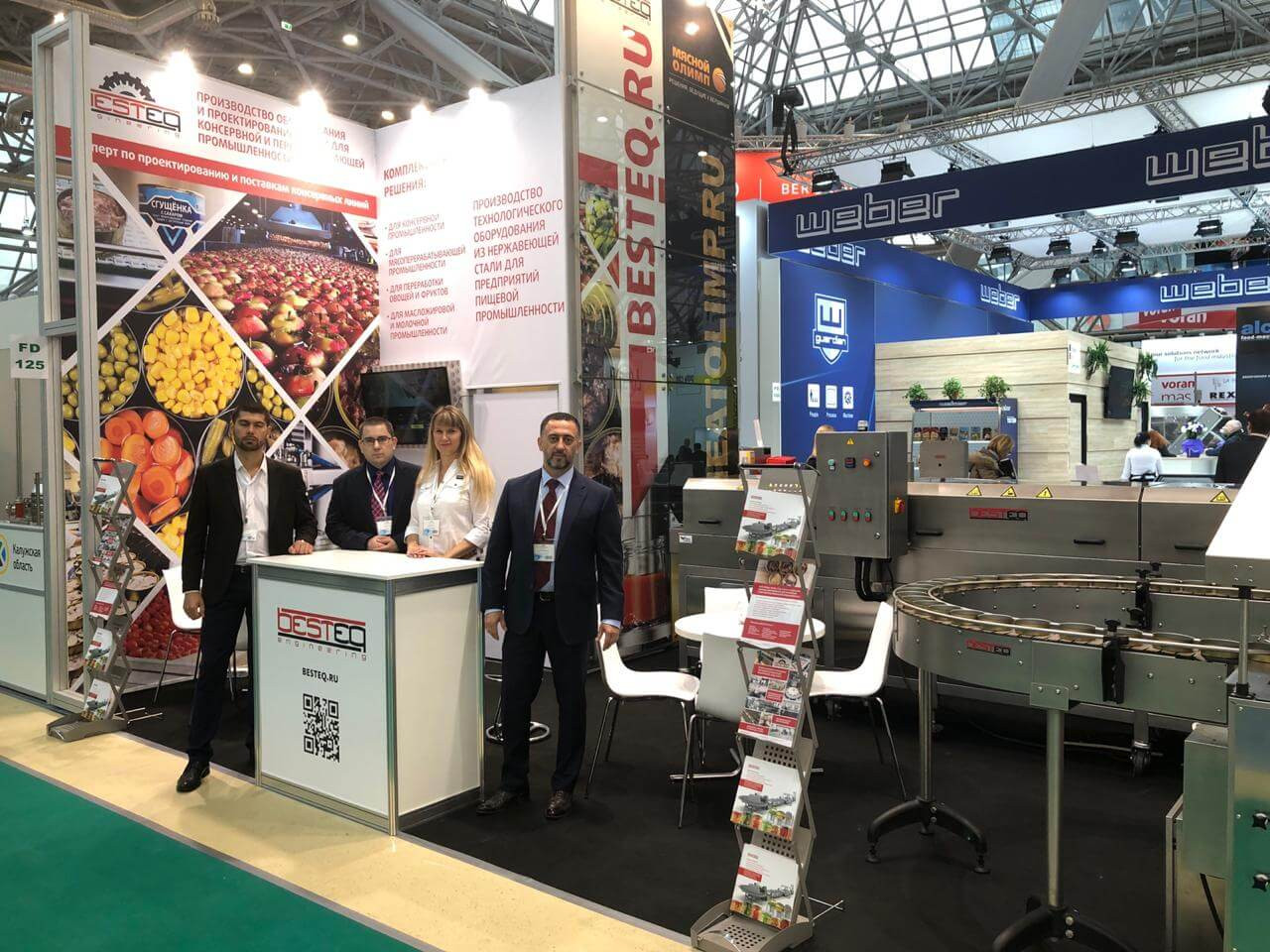

Im Jahr 2018 wurde das Unternehmen vom Landwirtschaftsministerium der Russischen Föderation als führend in der Importsubstitution anerkannt und erhielt auf der Messe Agroprodmash 2018 in Moskau ein Diplom in der Nominierung "Für Erfolge in der Importsubstitution".