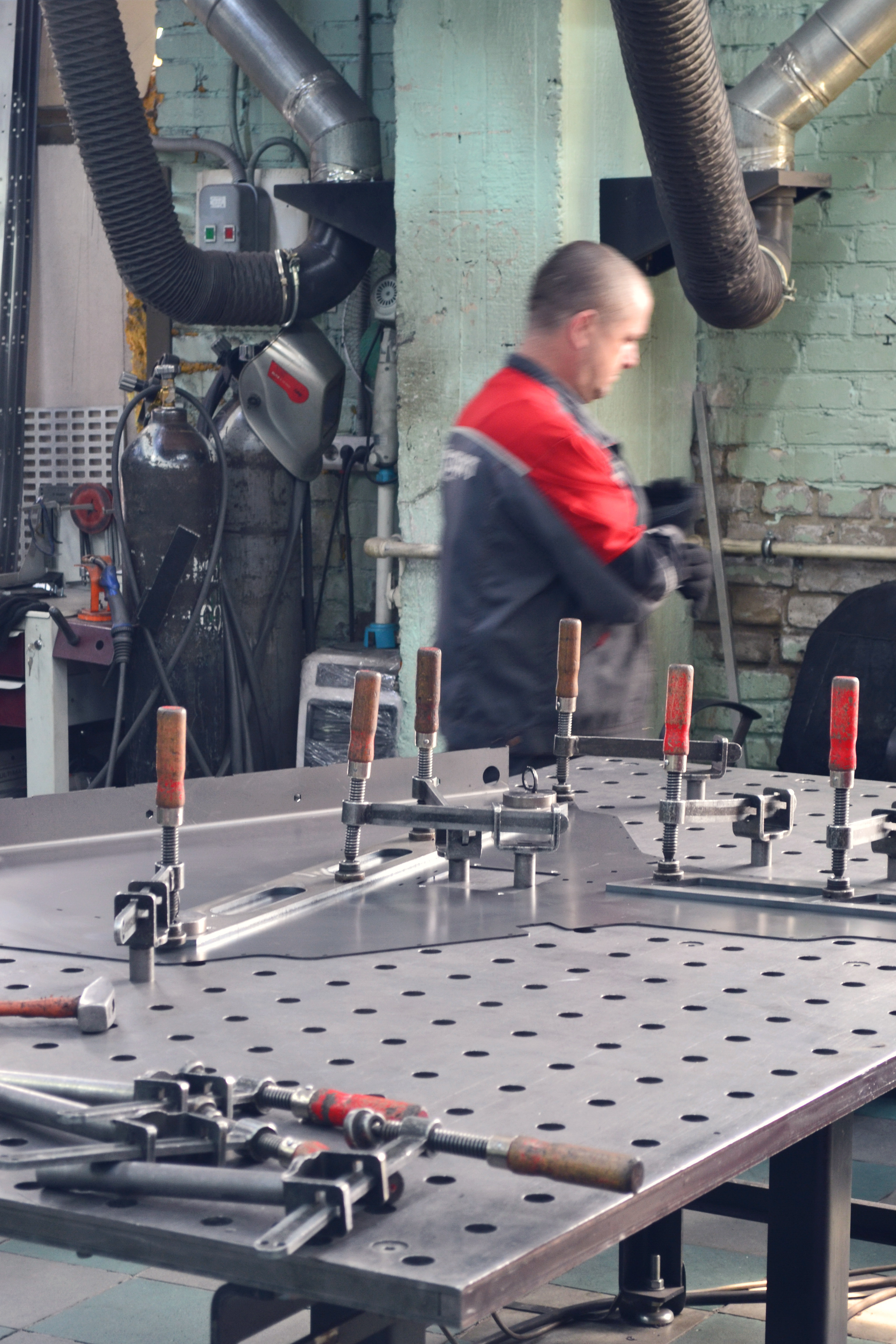

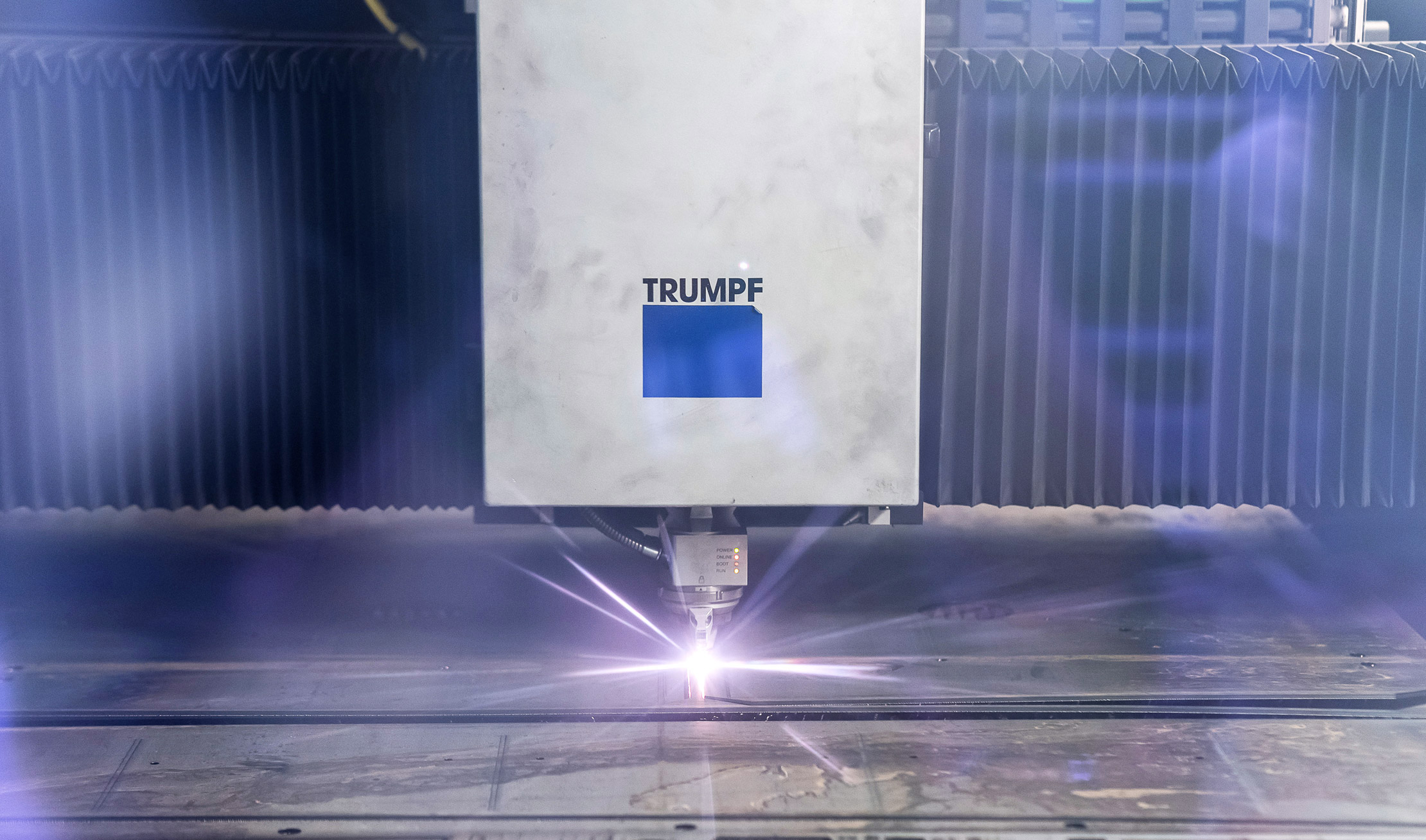

Since 2007, CSort has been developing and manufacturing high-tech equipment for sorting bulk products - color sorters. Today CSort is the Russian leader in terms of sales of its own color sorters; it is a member of the Rosspetsmash Association and the Altai cluster of agricultural engineering. CSort has representative offices in 9 countries of the world, equipment supplies go to 27 countries. In 2019, the company became a participant in the priority project of the Ministry of Economic Development of Russia "National Champions", and CSort was also recognized as the best exporter of Siberia in the nomination "Exporter of the Year in the Field of High Technologies" (competition of the Russian Export Center). CSort has representative offices in the following cities: Barnaul (head office); Voronezh; Krasnodar; Novosibirsk; Samara. The CSort plant is located in Russia. It includes a development center, a manufacturing facility, a quality assurance and control service, a sales office, and an international trade department.

Make a safe deal with this supplier.

Apply

LLC "CSort"

Russia

Specify the price

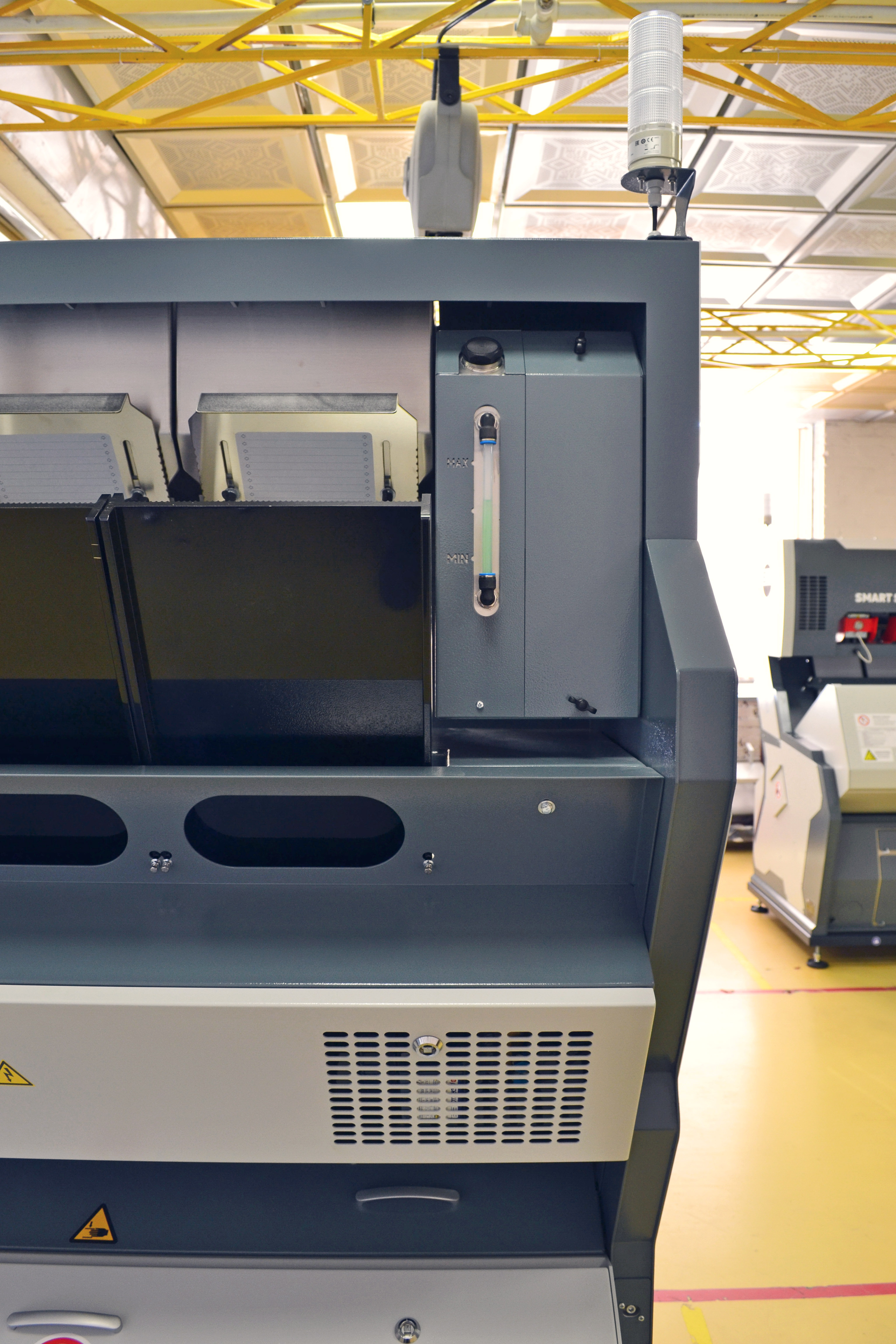

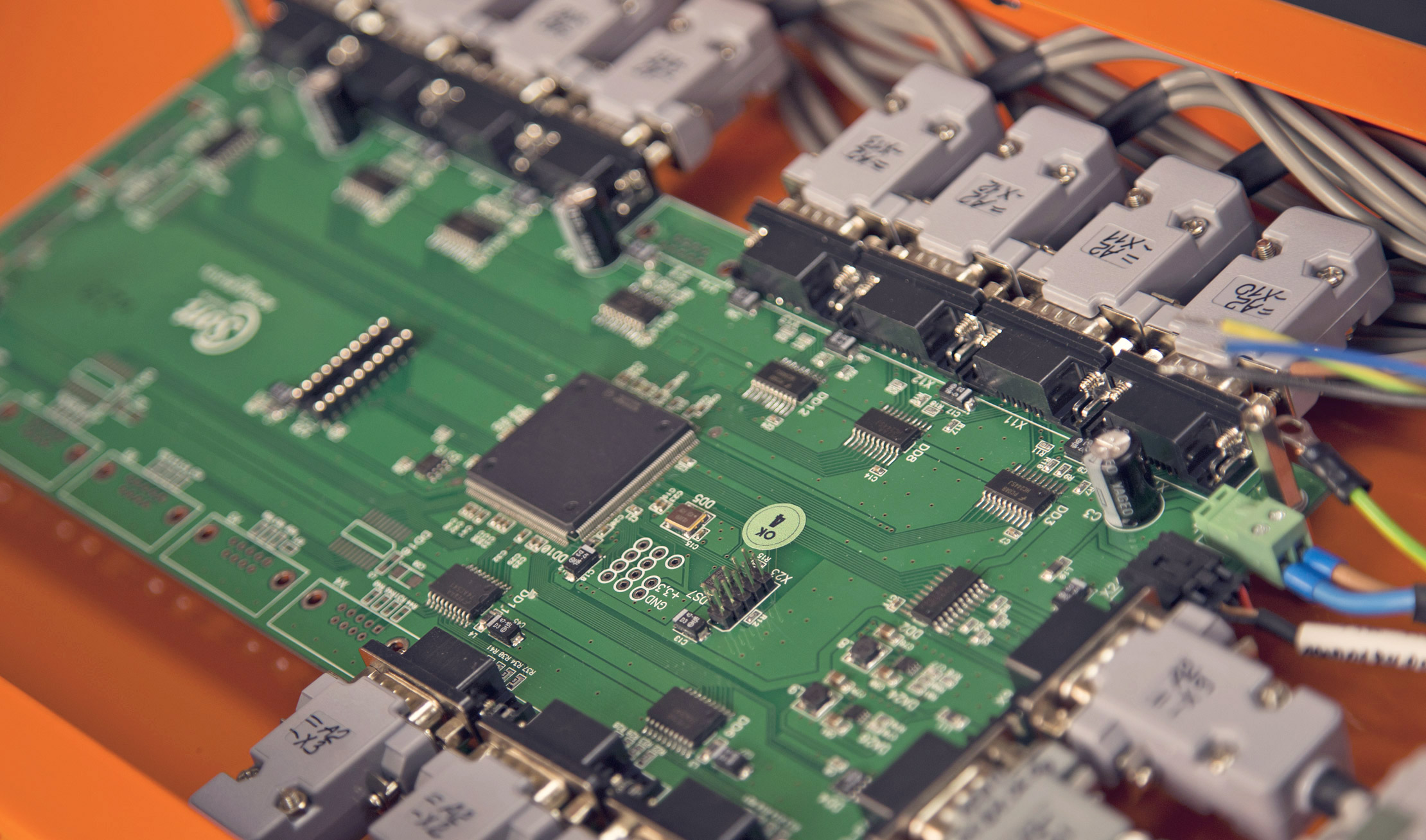

The SmartSort C 6 photo sorter is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 42 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo sorters independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo sorter, the CSort service team monitors the operation of the photo sorter 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime.

LLC "CSort"

Russia

Specify the price

The SmartSort C 5 photo sorter is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 35 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo sorters independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo sorter, the CSort service team monitors the operation of the photo sorter 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime.

LLC "CSort"

Russia

Specify the price

The SmartSort C 4 photo sorter is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 28 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo sorters independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo sorter, the CSort service team monitors the operation of the photo sorter 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime.

LLC "CSort"

Russia

Specify the price

The SmartSort C 3 photo sorter is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 21 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo sorters independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo sorter, the CSort service team monitors the operation of the photo sorter 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime. Improving the quality of commercial grain Preparation of seeds with low losses Sorting of wild plants Removal of difficult-to-separate impurities Preparation of raw materials in mini-mills Sorting of coffee for roasters and coffee shop suppliers Sorting of oilseeds Sorting of minerals Sorting of plastics by color (PET granules, flakes).

LLC "CSort"

Russia

Specify the price

The SmartSort C 2 photo sorter is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 14 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo sorters independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo sorter, the CSort service team monitors the operation of the photo sorter 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime.

LLC "CSort"

Russia

Specify the price

Photo separator SmartSort C 1 is suitable for sorting food and non-food bulk products and successfully solves problems with small-seeded products. Productivity up to 7 t/h. The number of cameras per tray is from 2 to 4, with a resolution of 5400 pixels operating in the visible and infrared range. Advanced AI (Smart mode) in SmartSort photo separators independently creates a sorting profile based on samples of good and bad products, taking into account differences in color and size, as well as in texture and shape. The selection of optimal parameters is carried out automatically and does not depend on the level of training of the technician. This ensures the best sorting results incorporated into the equipment by the developers. The accuracy of sorting and ease of operation are significantly influenced by the ability to automatically adjust all sections of the machine using one master chamber, implemented only in our software. Confidence in the stable operation of the equipment, in cases where the quality of the raw materials may be unstable, is ensured by intelligent adjustment of sorting parameters directly while the equipment is operating. Modern service increasing reliability. Using CSort Cloud and a digital twin of the photo separator, the CSort service team monitors the operation of the photo separator 24/7. We learn about dangerous and borderline sorting states long before the user notices it. At any time, including remotely, the service is ready to resolve emerging issues. All this allows you to avoid losses in sorting quality, reduce wear and prevent equipment breakdowns. This approach allows you to achieve uninterrupted operation and minimize costs due to equipment downtime. Improving the quality of commercial grain Preparing seeds with low losses Sorting wild plants Removing difficult-to-separate impurities Preparation of raw materials in mini-mills Sorting coffee for roasters and coffee shop suppliers Sorting oilseeds Sorting minerals Sorting plastics by color (PET granules, flakes).

LLC "CSort"

Russia

USD

54494.38/pcs

CUBER elevator storage storage is designed for storage of any goods in any industry and trade, it allows to significantly save the ground storage area due to the maximum use of space in height. Along with increasing the efficiency of warehouse processes, an elevator warehouse ensures safe and fast storage of goods in a clean and orderly manner, guarantees ergonomic and safe work. One of the main advantages of CUBER is that it can be used not only as an autonomous system, but also as an element of complex automation of production processes. Storage and selection of small goods Warehouse automation Warehousing and accounting.

LLC "CSort"

Russia

USD

2.04/pcs

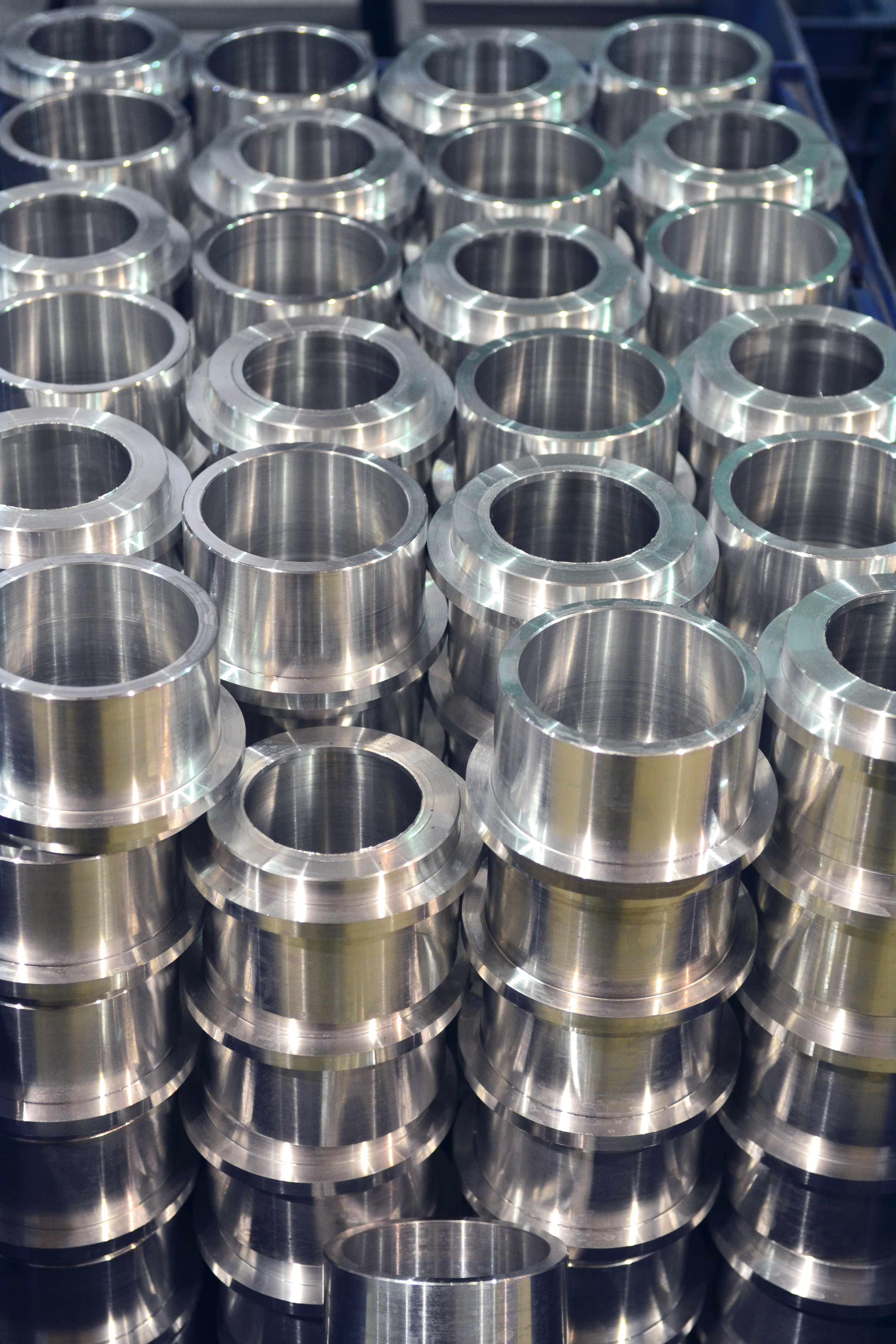

Modern CSE 180 bucket elevators from SeaSort, with a capacity of up to 180 m³/h, provide economical, fast and safe transportation of bulk material and can be used in various industries. CSE 180 bucket elevators are equipped with plastic buckets, the belt speed range is from 1.5 to 2.5 m/s, they can be used for transporting animal feed, grain or seeds. The start of the electric motor is smooth, which eliminates the possibility of breaking the buckets and cutting the keys on the upper head of the bucket elevator, and allows the use of electric motors of lower power. Convenience in repair, inspection, maintenance is inherent in the design features. Applications Transportation of bulk materials Transportation of compound feed Transportation of grain Transportation of seeds Can be installed outdoors

LLC "CSort"

Russia

USD

5285.5/pcs

Modern CSE 120 bucket elevators from SeaSort, with a capacity of up to 120 m³/h, provide economical, fast and safe transportation of bulk material and can be used in various industries. CSE 120 bucket elevators are equipped with plastic buckets, the belt speed range is from 1.5 to 2.5 m/s, they can be used for transporting animal feed, grain or seeds. The start of the electric motor is smooth, which eliminates the possibility of breaking the buckets and cutting the keys on the upper head of the bucket elevator, and allows the use of electric motors of lower power. Convenience in repair, inspection, maintenance is inherent in the design features. Applications Transportation of bulk materials Transportation of compound feed Transportation of grain Transportation of seeds Can be installed outdoors

LLC "CSort"

Russia

USD

0.92/pcs

Modern bucket elevators CSE 60 from SeaSort, with a capacity of up to 60 m³/h, provide economical, fast and safe transportation of bulk material and can be used in various industries. CSE 60 bucket elevators are equipped with plastic buckets, the belt speed range is from 1.4 to 2.5 m/s, they can be used for transporting animal feed, grain or seeds. The start of the electric motor is smooth, which eliminates the possibility of breaking the buckets and cutting the keys on the upper head of the bucket elevator, and allows the use of electric motors of lower power. Convenience in repair, inspection, maintenance is inherent in the design features. Applications Transportation of bulk materials Transportation of compound feed Transportation of grain Transportation of seeds Can be installed outdoors

LLC "CSort"

Russia

USD

2878.67/pcs

Modern CSE 30 bucket elevators from SeaSort, with a capacity of up to 30 m³/h, provide economical, fast and safe transportation of bulk material and can be used in various industries. CSE 30 bucket elevators are equipped with plastic buckets, the belt speed range is from 1.1 to 2.2 m/s, they can be used for transporting animal feed, grain or seeds. The start of the electric motor is smooth, which eliminates the possibility of breaking the buckets and cutting the keys on the upper head of the bucket elevator, and allows the use of electric motors of lower power. Convenience in repair, inspection, maintenance is inherent in the design features. Applications Transportation of bulk materials Transportation of compound feed Transportation of grain Transportation of seeds Can be installed outdoors

LLC "CSort"

Russia

Specify the price

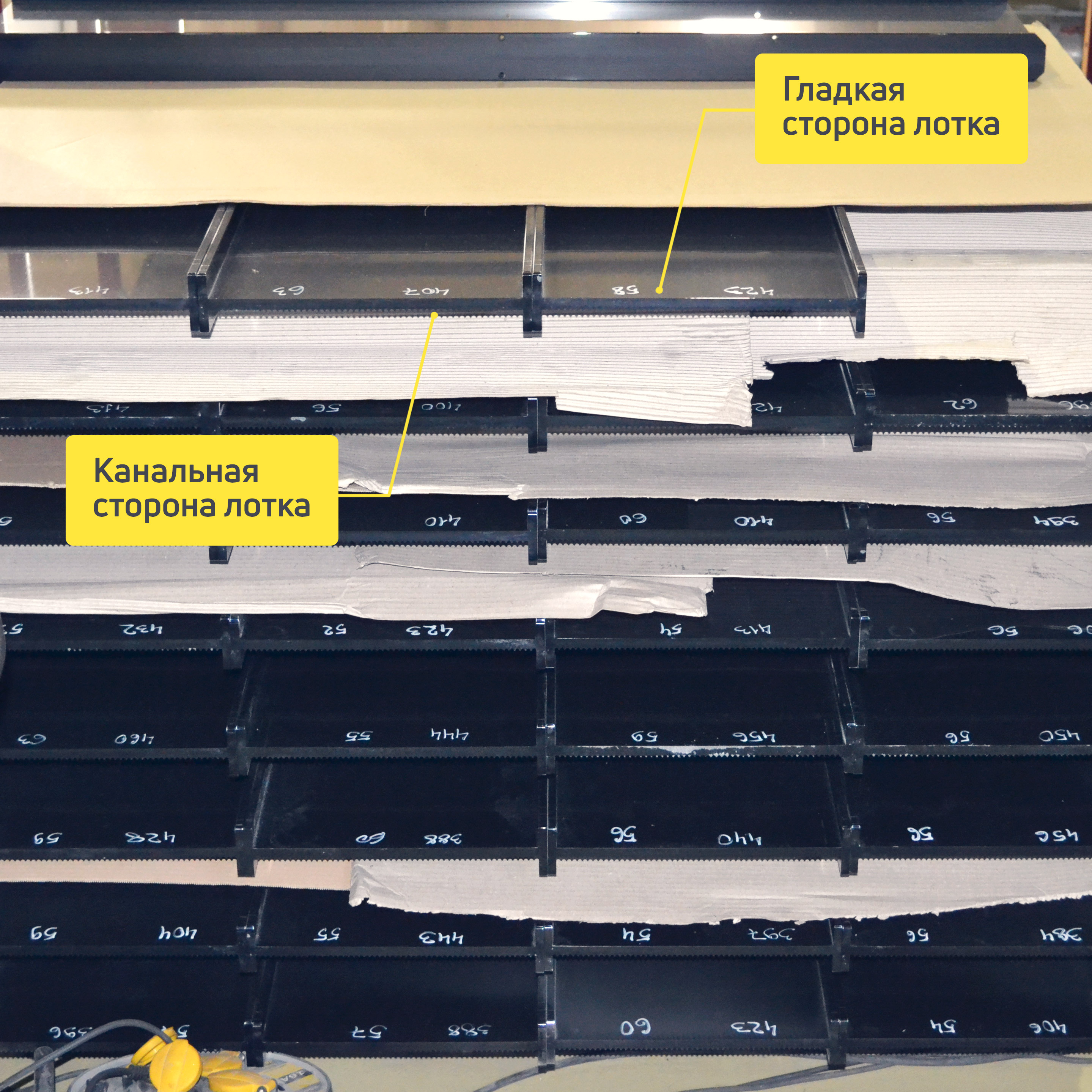

Универсальные фотосепараторы серии Horizont – это ленточные оптические сепараторы, которые применяются для сортировки пищевых и непищевых сыпучих продуктов, таких как орехи, зерновые и бобовые культуры, сушеные овощи и фрукты, кофе, замороженные продукты, чипсы и хлопья, а также для сортировки металлов, минералов и пластиков.

Важной особенностью ленточных (горизонтальных) фотосепараторов Horizont является то, что продукт сортировки анализируется со всех сторон — сверху тремя камерами над лентой транспортера, что позволяет видеть практически 100 % дефектов, и камерой на слете с него. Продукт поступает в поле зрения камер тонким, успокоенным слоем на ленте, что повышает точность анализа и удаления засорителей.

Благодаря меньшим скоростям чем на лотковых аппаратах продукт меньше травмируется — это расширяет диапазон применимости оптической сортировки.

Особенности конструкции позволяют адаптировать элементы под использование с абразивными продуктами, мокрыми и сухими, в т.ч. запыленными; требующими бережного отношения.

Фотосепаратор оснащен камерами высокого разрешения — 5400 пикселей работающих в видимом и инфракрасном диапазоне. Изображение полученное с камер анализируется интеллектуальной системой способной различать объекты не только по цвету, но и по сложным признакам — текстуры и формы, сортировка по 3D форме. Интеллектуальная система настройки способна сама себя подстраивать при изменении параметров входящего сырья, при минимальном вмешательстве оператора.

About company

Contact supplier

Supplier:

"Узлегпром"

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message