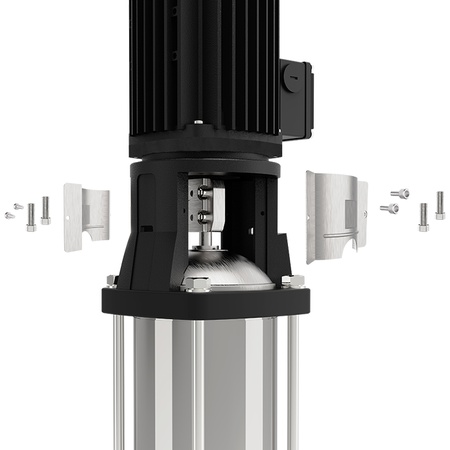

Product description

vertical multistage pump CDL2-12

vertical multistage pump CDL2-12

head 89 m

capacity 2 m3 / h

pump type multistage

voltage 380

pump material stainless steel AISI304

wheel material stainless steel AISI304

pump location vertical

power 1.5 kW

connection type thread

wheel type centrifugal

Description

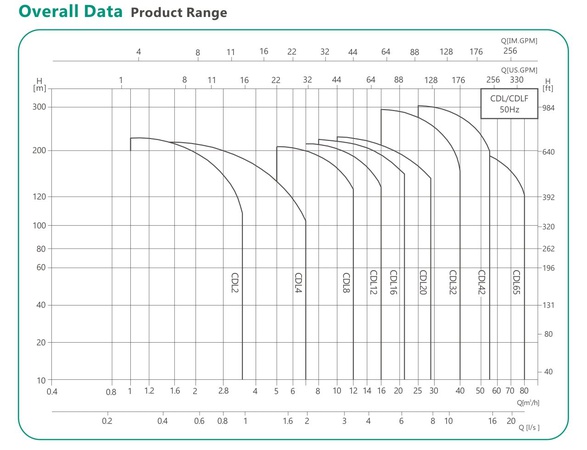

The CDL / CDLF is a versatile pump that can transport a variety of media, from tap water to industrial fluids, and is suitable for a variety of temperature, flow and pressure ranges. CDL is suitable for non-corrosive fluids and CDLF is suitable for moderately corrosive fluids.

Application

• Water supply: filtration and transportation in hydraulic structures, distribution of water in various zones of hydraulic structures, sealing of main pipes and sealing of high-rise buildings.

• Industrial applications: water supply system, purification system, high pressure washing system and fire extinguishing system.

• Industrial transport of liquids: refrigeration and air conditioning systems, boiler feed water systems and condensation systems, industrial machine support, acid and alkali pumping.

• Water treatment: ultrafiltration system, reverse osmosis system, distillation system, separator and pool.

• Irrigation: agricultural irrigation, rain and drip irrigation.

Technical details

• Temperature of liquid:

-15 ° C to + 70 ° C for standard pump type

from -15 ° C to + 120 ° C for hot water on request

• Ambient temperature: maximum + 40 ° C

• Materials of the pump - stainless steel AISI304 - standard pump type

• Materials of the pump - stainless steel AISI3 16 - on request

The principle of operation s

CDL / CDLF is a vertical multistage centrifugal pump for standard installation of the engine and pump hydraulics in a vertical position. The motor shaft is directly connected to the pump shaft through a central coupling. Flanges are flush in the -in-line position. Therefore, the pump can be configured with intelligent protection in the form of a remote control in accordance with the needs of the buyer and with the water supply project, such a system can perform effective protection, such as protection against pump dry run, phase failure, overload, etc.

Electric motor

• The electric motor is a fully enclosed air-cooled standard motor.

• Degree of protection: IP55.

• Insulation class: F

• Standard voltage: 50 Hz: 1 x 220-230 / 240 V

• speed of rotation 2900 rpm

3x200-220 / 346-380 V

3х220-240 / 380-415 V

3x380-415V

Learn more

Check availability

718.98

USD/pcs

718.98

USD

Minimum order: 1 pcs

Supply ability: 2 pcs/per month

Imported pumps

Not verified supplier

Харьков, Ukraine

Shipping information

Calculate and complete your cargo transportation worldwide using Qoovee Logistics.

Guaranteed shipment on time and secure payment Calculate shipping from QooveeSimilar products

USD

11.0/pcs

11.0

All the brands of Compressors we can provide:

CAT Compressors, KOMATSU Compressors, JOHN DEERE Compressors, SANY Compressors, XCMG Compressors, VOLVO Compressors, HITACHI Compressors, SUMITOMO Compressors, LIEBHERR Compressors, DOOSAN Compressors, CASE Compressors, BOBCAT Compressors, KUBOTA Compressors, YANMAR Compressors, HYUNDAI Compressors, DAEWOO Compressors, etc.

For other parts of the brands above we can also provide cylinder liners, crankshafts, oil pumps, solenoid valves, solenoid coils, fuel injectors, batteries, radiators, gaskets and seals, mufflers, manifolds, turbochargers, hydraulic pumps, hydraulic motors, hydraulic valves, hydraulic couplers, bearings, reducers, bearing seats, gears, pulley, sprocket, coupling, drive shaft assembly, brakes, clutches, drive chains, actuators, alternators, cables, controllers, distributors, fuses and relays, harnesses, sensors, switches, gearcases, filters, counterweights, heater and A/C accessories, belts, etc.

Hannemec Air Compressor

China

USD

2200.0 - 3000.0/pcs

Single screw air compressor is an industrial machine that compresses air by using a single screw rotor. It is commonly used in industrial settings for powering pneumatic tools, machinery, and equipment. It is known for its high efficiency, reliability, and low noise level.

Model NO.:HD7.5-8

Structure Type:Closed Type

Installation Type:Stationary Type

Type:Single Screw Compressor

Free Air Deliver:1 (M3/Min)

Pressure:8bar

Motor Power:7.5KW

Electricity:220V

Weight:140kg

Size:970*700*980(mm)

R & D Capability:OEM, Own Brand

Export Mode:Have Proprietary Import and Export Rights

Transport Package:Wooden Crate Pallet+Foam Board+Bubble Film Wrapped

Specification:ISO9001, CE

Trademark:Hannemec

Origin:LinYi, China

HS Code:8414804100

Production Capacity:1000PCS/Month

Hannemec Air Compressor

Linyi, China

USD

2000.0 - 3000.0/pcs

Applicable Industries Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

Showroom Location Egypt, Canada, Turkey, Italy, France, Germany, Peru, Saudi Arabia, Indonesia, Mexico, Russia, Spain, Thailand, South Korea, Chile, UAE, Romania, Bangladesh, South Africa, Kazakhstan, Nigeria, Uzbekistan, Tajikistan, Japan

Place of Origin Shandong, China

Warranty 1 Year

Working Pressure Other, 13, 16

Machinery Test Report Provided

Video outgoing-inspection Provided

Marketing Type New Product 2021

Warranty of core components 2 years

Core Components PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox, airend

Gas Type Air

Condition New

Type Screw

Configuration Stationary

Power Source AC POWER

Lubrication Style Lubricated

Mute Yes

Brand Name HANNIMIKE

Model Number 22kw 16bar, 7.5kw 13bar, 11kw 16bar, 15kw 16bar, 37kw 16bar

Voltage 220V/380v/Customizable

Dimension(L*W*H) 1800*730*1700

Weight 420KG-800KG

Product name TSE22-16

Packaging & delivery

Package Type: wooden box package

TOO "Novi Trade"

Kazakhstan

USD

33033.71/pcs

33033.71

The DPVO 550 models feature a wide swivel angle of 20° and a high head capacity. 100% through drive and can be combined with hyperbolic power control with pressure control and pressure shutdown. Nominal pressure pN = 5,511 psi (380 bar) Maximum pressure pmax = 6,092 psi in. (420 bar) Displacement 550m3 Volume flow at Vg max and nmax 797 Maximum speed at Vg max and pabs = 1 bar at suction port 1450

USD

350.0/pcs

350.0

Self-priming pump CBH-80 and its units (hereinafter referred to as pumps or units) are designed to pump liquids without mechanical impurities. Pump CBH-80 is designed to pump the following liquids: water, gasoline, kerosene, diesel fuel and other liquids with a viscosity of not more than 2×10-6m2/s at a temperature from -40̊С to +50̊С and a density of not more than 1000 kg/m3.

Symbol of a pump or electric pump unit:C – self-priming(самовсасывающий);B – vortex (вихревой);H-pump (насос);80- DN inlet and outlet pipe, mm

Specifications of Pump CBH-80

The main technical characteristics of the pump are shown in Fig . 1 and in Table 1 at testing it on water at a temperature of 20 °C and a rotational speed of 1450 rpm.

Model

CBH-80

Rated pump power, W

7500

Voltage, V

380

Rotation frequency, s-1 (rpm)

1450

Direction of pump rotation

Right or Left

Supply,m3/h

30

Rated head, m

26

Self-priming height, not less than, m

6.5

Self-priming time, no more than, s

120

Permissible duration of self-priming, no more than, s

300

Leakage through the mechanical seal, not more than cm3/h

30

Electric motor power, kW

11 or 15

Pump weight

19kg

USD

120.0/pcs

120.0

AHCB-2 series oil pump belongs to inside sealed slip blade self-priming pump. It is one of our up-to-date products developing and producing by ourselves. This pump have awarded two patent. Compared with other pumps, the advantage of this oil transfer pump is that it can pump and deliver oil automaticly without puring oil into the pump. At the same time, the pump is oil-resistance, general impurity-proof and air-proof. So, when cleaning the remaining oil at the bottom of oil tank or truck, it will be high efficiency, fuel-saving by using AHCB-2 series oil transfer pump. For now, these AHCB-2 series oil pumps have obtained a number of national patents, passed the GB/T19001-ISO9001:2015 standard certification, and obtained the quality management system certificate. Meanwhile, these pumps also have obtained the explosion-proof certificate of the National Explosion-proof Electrical Product Quality Supervision and Inspection Center, and the explosion-proof mark ExdellBT4Gb+E.xcllT4Gb.

Applications of AHCB-2 series Oil Pump

◈ This series pump can be widely used in oil storage depots, gas stations, railways, docks and other oil loading and unloading operations.◈ It can transport gasoline, diesel, kerosene, methanol, ethanol and other oil products and liquid raw materials.◈ Explosion-proof flexible vane pump, in addition to the above performance, due to the continuous reciprocating elastic working principle structure of the vanes in the pump chamber (the vanes are made of special rubber materials), which makes it oil-resistant, corrosion-resistant, wear-resistant and flex-resistant. Therefore, these pumps are more suitable for use as oil tanks, oil tank trucks, oil tanks and other occasions, cleaning the bottom oil, cleaning up oily garbage, has more superior performance, and has significant work efficiency and economic benefits.

USD

20.0/m

20.0

We offers high quality hose for oil & gas recovery. Gas station oil and gas recovery refers to the collection of volatilized gasoline oil and gas during the process of loading and unloading gasoline and refueling vehicles, or reducing the pollution of oil and gas by one or two methods of absorption, adsorption or condensation, or change the oil and gas from gaseous to liquid, and then to gasoline again, so as to achieve the purpose of recycling.

The oil and gas recovery coaxial hose is used in the oil and gas recovery system of the oil dispenser. During the refueling process, it is connected to the oil and gas recovery fuel nozzle and the oil and gas separation valve. Between the middle layer and the outer wall is an oil circuit, and the middle pipe is a gas circuit. When refueling, the oil and gas are drawn into the underground oil tank from the gas circuit. The metal braid of the tube provides excellent kink resistance, low elongation and long service life.

Aztoolspro.com

Indonesia

USD

1189.0/pcs

1189.0

Price: $1,189 per item. Minimum order: 1 piece ALC Abrasive Pressure Jet - 250 lbs. Tank Model No. 40005 This ALC® blaster is ideal for a wide range of surface preparation applications such as paint, scale, rust and oxidation removal. Ideal for surface preparation of cars, trucks, equipment, pickling steel, glass and more. Features 25ft. Durable Goodyear blast hose designed for long life and maneuverability. Sturdy wheels and integrated handle make it easy to transport. Sturdy steel locking handle for durability and safety. Simply add abrasive and turn on the air supply and you are ready to blast. Some assembly required. What's Included (1) Blast Unit P/N 155315 Brand ALC Manufacturer's Warranty 24 months parts / 24 months labor Shipping weight 137.0 lbs Abrasive capacity (lbs) 250 Load air flow (cfm) 7 - 80 Working psi in. 80–125 Body Material Steel Body Finish Powder coating Recommended Media Black Beauty, steel powder, glass beads Hose (in. x ft.) 1/2 x 25 Deadman Relief Valve Yes Gun Included Yes Nozzle Size (in.) 1/8, 5 /32 Water separator Yes Tire size (in.) 10 Dimensions L x W x H (in.) 16 x 16 x 40 in.

Aztoolspro.com

Indonesia

USD

1609.0/pcs

1609.0

Price: $1,609 per item. Minimum order: 1 piece ALC steel blast cabinet with LED lighting, 36" Model No. 40403L. This ALC® steel blast cabinet is a rugged 36" cabinet. x 24 inches. steel shot blast cabinet made of 14-ga. steel with reinforced corner iron legs. Fully welded construction means no leaks. The 36" (W) x 24" (H) x 24" (D) internal work area accommodates a wide variety of items with access through the side door. The included ultra-bright LED light and 112 CFM dust collector help the operator maintain good visibility even during heavy blasting. Also includes a 1/4" foot-operated gun. nozzle, high quality 24in. lined gloves, lined foam hand openings and window protector. Fully opening top door and side door. What's Included (1) ALC 40403L Shot Blasting Cabinet with LED Light Kit (1) Pair of Sandblasting Gloves (1) Foot Control (1) 1/4" Gun. Nozzle Product Guide Key Features P/N 89455 Trademark ALC Manufacturer's Warranty 1 Year Limited Warranty Shipping Weight 300.0 lbs. in. 80–125 Air Consumption (cfm) 15 min. cfm x 35 Side Door Dimensions (in.) 11 x 17 Window Dimensions (in.) 12 x 24 Recommended Media Any type of dry abrasive such as glass beads, plastic chips, aluminum oxide, and silicon carbide Media Capacity (cu. ft.) Min. . 50 lb Gun Included Yes Nozzle Size (in) 1/4" Gloves Included Yes Pedal Included Yes Dimensions W x D x H (in) 36 x 24 x 60 Item Weight 272 lbs

Aztoolspro.com

Indonesia

USD

1259.0/pcs

1259.0

Price: $1,259 per item. Minimum order: 1 piece BelAire Electric Air Compressor - 5 HP Two Stage 80 Gallon Vertical 14.7 CFM Model #4918VN. This 5 HP BelAire 2 Stage Electric Air Compressor tools! What's Included (1) 5HP Electric Two Stage Air Compressor with 80 gallon vertical tank. Product Guide. Key Features Art. No. 112689 Brand BelAire. Manufacturer's warranty. /240 Stage 2 CFM at 90 PSI 15.6 Max. 165 cu. ft/min at 40 psi inch 16 cu. ft/min at max. 14.7 psi

Aztoolspro.com

Indonesia

USD

2113.0/pcs

2113.0

Price: $2,113 per item. Minimum order: 1 piece Campbell Hausfeld Two Stage Air Compressor - 5 HP, 208-230/460V, 3-phase, 80 gal horizontal, 16.6 cfm, 175 psi, model # CE7053. The Campbell Hausfeld™ Shop Air Series compressor is ideal for general compressed air needs including machine shops, dry cleaners, auto repair shops, woodworking shops or general industrial applications. Equipped with cast iron two stage pump for long life, ASME certified tank (200 psi max) and NEMA industrial motor for reliable performance. The installed and connected motor starter provides a quick electrical connection. Fully enclosed metal belt guard ensures safe operation. USA What's Included (1) Air Compressor Product Manual Key Specifications P/N 3751799 Brand Campbell Hausfeld Manufacturer's Warranty 3 Year Limited Warranty Ship Weight 560.0 lbs HP 5 Air reservoir size 80 Volt 208-230/460 Stage 2 cc PSI 175 Air Outlet Size 3/4 Phase Motor 3A 14.2-13/6.5 Duty Cycle 80% Pump Life 17,500 Drain Type Manual Weight (lbs) 560 Dimensions L x W x H (in) 25 x 68 x50

Aztoolspro.com

Indonesia

USD

5424.0/pcs

5424.0

Price: $5,424 per item. Minimum order: 1 piece Campbell Hausfeld 2-in-1 Gas Air Compressor/Generator - Honda GX390 Engine, 10 Gallon, Model # GR2100. Whether you need to run electricity to a construction site or your home has experienced a power outage due to harsh weather, this Campbell Hausfeld 2-in-1 Honda-powered air compressor/generator provides compressed air and power to meet your needs. This unit is ideal for commercial and industrial applications on the construction site and in mobile services. It is powered by a reliable Honda GX390 gas engine. The two-stage cast iron air compressor provides high performance and reliability, with two 5 gallon air tanks and a strong steel belt guard for safety. The 5000W generator has a UL/OSHA compliant control panel and 3 GFCI protected outlets. 49.8" L x 26" W x 34.5" H. What's Included (1) 2-in-1 Air Compressor/Generator with Honda Engine, Model # GR2100 Key Features Part # 44911 Brand Campbell Hausfeld Manufacturer's Warranty 1 Year Limited warranty Ship weight 486.0 lbs HP 13 HP 14.3 psi inch Max. PSI 175 Stage 2 Duty Cycle 100% 50A / 65% 180A Tank Orientation Horizontal Twin Dimensions L x W x H (in) 49 2/5 x 26 x 34 1/2

Suppliers in this category

All suppliers in the category

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message