Production of industrial refrigeration and compressor equipment. For more than 50 years, the company has been exporting ozone-friendly refrigerants, compressor equipment. The engineering and production personnel of the plant mastered over 200 items of refrigeration equipment of medium and high complexity. And now, for the convenience of delivering orders on the territory of the Russian Federation, a representative office has been opened in Belgorod. Here you can buy refrigeration equipment and order its repair. more than 50,000 customers worldwide 80 years of operation uninterrupted operation of equipment up to 20 years about 500,000 completed projects

Make a safe deal with this supplier.

Apply

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

MVT36-2-0 Designed for cooling a liquid coolant in air conditioning systems, cooling systems for milk, soft drinks, beer, sparkling wines, oils using an intermediate coolant. It is used on dairy farms, food industry enterprises, in air conditioning systems.

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

Stand-alone air conditioner AKV-4.5 with air-cooled condenser, designed for cooling, heating and purifying air in industrial premises, control rooms, equipment rooms, electrical halls, office rooms, at ambient temperatures up to + 45 ° C. Provides maintaining the required air temperature in the range from 12 ° C to 28 ° C, with an accuracy of ± 1 ° C. The air conditioner is equipped with compressors and components of the world's leading manufacturers in the field of refrigeration - Copeland, Danfoss, Bristol. NAME OF PARAMETERS \ MODEL AUTONOMOUS AIR-CONDITIONER AKV-4,5 Productivity on cold, kW 21,0 Productivity on heat, kW 12,0 Nominal air consumption, m3 / h 4500 External static pressure, Pa 300 Degree of air purification,% 90 Refrigerant R -22 Power supply 380 V / 3ph / 50 Hz Power consumption (in cooling mode), kW 8.9 Evaporator type Copper tubes with aluminum fins Condenser type Copper tubes with aluminum fins TRV refrigerant flow regulator TRV refrigerant flow regulator Fan (centrifugal with double external suction): drive: belt; power: 1,5 kW. Overall dimensions (length x width x height), mm: air handling unit: 520 x 1200 x 1800; condenser unit: 650 x 1500 x 850. Weight, kg: air handling unit: 265; capacitor block: 110.

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

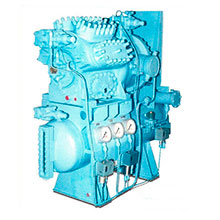

It has a V-shaped design, is able to switch to two modes of operation on R-12 freon. The first allows you to issue cooling capacity of 14.9 kW, spending 5.0 kW. The second mode allows lower rates: 10.5 kW in the cold and 3.4 kW of energy consumption. The FV6 compressor and the FU 12 compressor are one of the most popular models in their segment. They are installed in powerful refrigeration units and units that are used in the Navy, in the metallurgical, mining, chemical, energy industries and special purpose facilities. Spare parts and the complete assembly of the FV 6 Freon compressor can be bought at manufacturer prices from the official distributor of the Refma factory in Belgorod. To contact managers, fill out the contact form, call the above phone numbers or send an e-mail to the company. The FU12 compressor is one of the main elements of the refrigeration unit and serves to carry out a continuous refrigeration cycle by constantly aspirating the refrigerant vapor from the evaporator and compressing them to condensation pressure. Designed to work as part of automated stationary and transport refrigeration units and air conditioners. NAME OF PARAMETERS \ MODEL COOLING COMPRESSOR ФУ12 Compressor type Freon compressor, piston, V-shaped, single-stage, cross-axle with external drive. MODE 1 Cooling capacity, kW (kcal / h) 14.9 (12800) Effective power, kW 5.0 Volume described by pistons, m3 / h 62.0 Cooling capacity and effective power are indicated in the mode, ° С during operation on R-12 on the mode: boiling point minus 15 ° С; condensation temperature 30 ° C; suction vapor temperature 15 ° C; shaft rotation speed 24 s-1 (1440) (rpm). MODE 2 Cooling capacity, kW (kcal / h) 10.5 (9000) Power consumption, kW 3.4 Volume described by pistons, m3 / h 41.4 Cooling capacity and effective power are indicated in the mode, ° С during operation on R-12 on the mode: boiling point minus 15 ° С; condensation temperature 30 ° C; suction vapor temperature 15 ° C; shaft rotation speed 16 s-1 (960) (rpm). Cylinder diameter, mm 67.5 Piston stroke, mm 50 Number of cylinders, pcs 4 Freon refrigerant 12 Brand of used oil ХФ12-16 (for R-12) Amount of refilled oil, kg 2.5 ± 5% Weight, kg 90 Overall dimensions (length x width x height), mm 484 x 530 x 426

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

Compressor FV6. It has an external drive and operates in 3 modes. The first uses R-12 freon. The device is capable of achieving 7.5 kW of cooling capacity, while consuming no more than 2.5 kW of energy. The second mode also includes operation on R-12 freon, but the compressor produces up to 5.35 kW, spending 1.7 kW of energy. The third mode is activated when refueling with R-22. This makes it possible to generate 11.05 kW of cooling capacity, using 4.2 kW of electricity. The FV6 compressor is one of the main elements of the refrigeration unit and serves to carry out a continuous refrigeration cycle by constantly aspirating the refrigerant vapor from the evaporator and compressing them to condensation pressure. Designed to work as part of automated stationary and transport refrigeration units and air conditioners. NAME OF PARAMETERS \ MODEL REFRIGERATING COMPRESSOR ФВ6 Compressor type Freon compressor, piston, vertical, single-stage, cross-axle with external drive. MODE 1 Cooling capacity, kW (kcal / h) 7.5 (6500) Effective power, kW 2.5 Volume described by pistons, m3 / h 31.0 Cooling capacity and effective power are indicated in the mode, ° С during operation on R-12 on the mode: boiling point minus 15 ° С; condensation temperature 30 ° C; suction vapor temperature 15 ° C; shaft rotation speed 24 s-1 (1440) (rpm). MODE 2 Cooling capacity, kW (kcal / h) 5.35 (4600) Power consumption, kW 1.7 Volume described by pistons, m3 / h 20.7 Cooling capacity and effective power are indicated in the mode, ° С during operation on R-12 on the mode: boiling point minus 15 ° С; condensation temperature 30 ° C; suction vapor temperature 15 ° C; shaft rotation speed 16 s-1 (960) (rpm). MODE 3 Cooling capacity, kW (kcal / h) 11.05 (9600) Power consumption, kW 4.2 Volume described by pistons, m3 / h 31.0 Cooling capacity and effective power are specified in the mode, ° С during operation on R-22 on the mode: boiling point minus 15 ° С; condensation temperature 30 ° C; suction vapor temperature 15 ° C; shaft rotation speed 24 s-1 (1440) (rpm). Cylinder diameter, mm 67.5 Piston stroke, mm 50 Number of cylinders, pcs 2 Refrigerant R12 or R22 Brand of used oil ХФ12-16 (for R-12) or ХФ22с-16 (for R-22) Amount of refilled oil, kg 1 , 7 ± 5% Weight, kg 50 Overall dimensions (length x width x height), mm 368 x 324 x 392

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

A heat pump is a machine that can transfer heat from a colder environment (air, earth, solar radiation, water from underground strata, water from open reservoirs, water from a common network, heat recovery, industrial waste water) to a hotter one (air, water and other). Under certain conditions, a heat pump with a compressor having a 1 kW electric motor as a drive can provide a thermal power of 3-5 kW, although it is known that the simple heat generation on a resistance with an electric power of 1 kW cannot exceed 1 kW. INSTALLATION APPLICABLE COMPRESSOR REFRIGERANT OVERALL DIMENSIONS, MM WEIGHT (NET), KG NKV60-2-8 “air-water” 5PB20-2-024 - 2 pcs. R22 1280x1830x1860 1300

LLC "ENERGOSERVICE-M"

Ukraine

Specify the price

A heat pump is a machine that can transfer heat from a colder environment (air, earth, solar radiation, water from underground strata, water from open reservoirs, water from a common network, heat recovery, industrial waste water) to a hotter one (air, water and other). Under some conditions, a heat pump with a compressor having a 1 kW electric motor as a drive can provide a heat power of 3 to 5 kW, although it is known that the simple heat generation on a resistance with an electric power of 1 kW cannot exceed 1 kW. INSTALLATION APPLIED COMPRESSOR REFRIGERANT OVERALL DIMENSIONS, MM WEIGHT (NET), KG ТХУ6-4-0 “water-water” 5PB10-4-0 R142 1730х500х760 350 ТХУ-14 “water-water” 5ПБ10-2-024 R22 unit 1800х57014 780х570х2000 installation of 620 block of tanks 65 ТХУ24-4-0 "water-water" 5PB50-4-0 R142 2275х620х1010 840 НКТ5-4-9 "water-water" 5ПБ10-4-0 R142 2320х520х1130 560 НКТ10-4-9 "water- water "5PB20-4-0 R142 2285x560x1200 670

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

Designed for pumping air and gases, non-aggressive to gray cast iron, structural steel and mineral oil, and explosion-proof in the conditions of the flow part and gear reducer. It is used ONLY with a fore-vacuum pump and is the second stage of vacuum. It is used in the following processes: drying of transformers and other devices; impregnation of windings, cable, wood and other materials; distillation in metallurgy upon receipt of non-ferrous metals, as well as chemically pure substances in the chemical and pharmaceutical industries; freeze-drying of products, biologically active preparations, vaccines; melting, casting, alloying of metal alloys; sintering of fine-grained and powdery materials in powder metallurgy, during sintering, coking, in the manufacture of refractory products. The DVN pump consists of the pump itself, mounted on the foundation frame, and connected to it by means of an elastic finger coupling of the electric motor. Cooling of the pumps 2ДВН-500 - air, 2ДВН-1500 - water. NAME OF PARAMETERS \ MODEL PUMP VACUUM 2DVN-1500 Speed of action, not less than, l / s 1500 Differential pressure, not more than, kPa 1,0 Maximum residual total pressure, Pa 0,5 Electric motor power, kW 11 Cooling water consumption, l / h 360 Weight, kg 830 Overall dimensions (length x width x height), mm 1840 x 580 x 850 Designation of the recommended fore-vacuum pump NVZ-180

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

The compressor 2FVBS4 / II OM4 is one of the main elements of the refrigeration unit and is used to carry out a continuous refrigeration cycle by constantly aspirating the refrigerant vapor from the evaporator and compressing them to a condensing pressure. Designed to work as part of automated ship refrigeration units and air conditioners. NAME OF PARAMETERS \ MODEL REFRIGERATING COMPRESSOR 2FVBS4 / II OM4 Compressor type freon compressor vertical, piston, single-stage, bezreztskopfny glandless. Cooling capacity, kW (kcal / h) 5.2 (4500) Power consumption, kW 2.2 Volume described by pistons, m3 / h 20.6 Cooling capacity and effective power are indicated in the mode, ° C when working on R-12 in the mode: boiling point minus 15 ° С, condensation temperature 30 ° С, suction vapor temperature 20 ° С liquid temperature in front of the throttle device 25 ° С Type of built-in electric motor АПВ2-41-6Ф Electric motor power, kW 2,1 Supply voltage, V 380 Rod alternating current, 3-phase Current frequency, Hz 50 Diameter of cylinder, mm 67.5 mm Ho d piston, mm 50 mm Number of cylinders, pcs 2 Synchronous speed, s-1 (r / min) 16.7 (1000) Volume described by pistons, m3 / h 20.6 Refrigerant R-12 Brand of used oil ХФ12- 16 Amount of refilled oil, kg 2.5 ± 5% Weight (dry) of the compressor, kg 130 Overall dimensions (length x width x height), mm 595 x 370 x 455

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

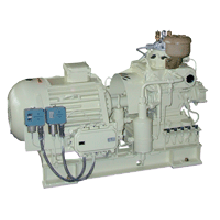

COMPRESSOR HIGH PRESSURE UNITS of the EKPA-2/150 series are intended for forcing air into cylinders and automatically maintaining pressure in them within 150 kgf / cm2 or 200 kgf / cm2. Used: · to start diesel-electric units; · For filling cylinders of breathing apparatus. The installation consists of a compressor and an electric motor. The compressor is three-stage. Circulating pressure lubrication from gear pump. Cooling - with seawater from a vortex type pump. Installation management is automatic. Installations are made in tropical marine execution. At the request of the customer can be made in marine export or marine tropical designs. The automatic control and protection system provides: - automatic start-up of the installation at a system pressure of less than 80 kgf / cm2; - automatic stop at a pressure in the system of 150 or 200 kgf / cm2; - emergency stop when the oil pressure in the lubrication system is reduced to 0.5 kgf / cm2; - emergency stop when the air temperature rises after the refrigerator of the first stage to 60 ° C; - Alarms on the automatic control panel for each emergency stop.

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

Designed to work as part of refrigerators for cooling air or liquid refrigerants with condensers of water or air cooling. Units consist of a compressor, receiver, filter - dryer, instrument panel, pressure gauge shield, connecting piping mounted on the frame. NAME OF PARAMETERS \ MODEL REFRIGERATING UNIT AKP14-15 Cooling capacity, kW * 16.9 Power consumption, kW 5.8 Receiver capacity, l 15 Temperature for nominal operation, ° С To = minus 15 ° С Тk = plus 30 ° С Rated refrigerant R22 freon mode Units are also operable with R12, R502 freon agents. The range of units in other modes is boiling point, ° С - from 10 to minus 40; condensation temperature, ° С - up to 50; ambient temperature, ° C - from 5 to 40; water temperature for cooling the condenser, ° С - up to 33.

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

Crane air conditioners of the KK series with air-cooled condenser are designed to create a comfortable air temperature in the cabins of bridge electric, gantry cranes, and other industrial premises, ensuring the maintenance of the required temperature. The temperature control range is from + 12 ° С to + 30 ° С with an accuracy of ± 0.5 ° С, at an ambient temperature from -25 ° С to + 65 ° С on ozone-safe freon R-134a, and up to + 80 ° С on R-142 freon or ozone-safe freon. R-227 Used in coke, ferroalloy and metallurgical industries. Air conditioners are equipped with hermetic or semi-hermetic compressors of the world's leading manufacturers - Copeland, BOCK, and fans - EBM Papst, ZIEHL-ABEGG made in Germany. Air conditioning is controlled by a control panel, which includes a programmable controller. Air conditioners work from sources of alternating current 380V and direct current 220V. Additionally, air conditioners are equipped with an air heater.

LLC "ENERGOSERVICE-M"

Ukraine

USD

1.0/pcs

NAME OF PARAMETERS \ MODEL AIR COMPRESSOR 4VU1-5 / 9M32 Final overpressure, kgf / cm2 8 Productivity, m3 / min according to the suction conditions: 5 compressed air: 0.56 Engine power, kW - Crankshaft rotational speed, rpm 735 Weight , kg 750 Overall dimensions, mm 1110 x 960 x 1110 Oil heating in the crankcase -

About company

Contact supplier

Supplier:

"Узлегпром"

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message