Product description

Description

Autoclave Black Dragon 12 liters class B for tattoo studios.

Programmes:

Programmes

Temperature

Pressure

Sterilisation time

Total time

Type

Max. load

Max. load per tray

Solid

134 0C

210 kPa

4 min

14-30 min

Solid unwrapped

4 Kg

1.2 Kg

1210C

110 kPa

20 min

30-45 min

Wrapped

134 0C

210 kPa

4 min

30-45 min

Solid unwrapped

3.5 Kg

1.1 Kg

121 0C

110 kPa

20 min

35-55 min

Solid or hollow simple wrapped

3.5 Kg

1.1 Kg

Liquid

134 0C

210 kPa

10 min

30-55 min

Liquid

0.80 kg

0.25 kg

121 0C

110 kPa

30 min

35-60 min

Textile

134 0C

210 kPa

8 min

30-50 min

Porous unwrapped

1 Kg

0.3 Kg

Porous simple wrapped

0.75 Kg

0.2 Kg

121 0C

110 kPa

30 min

40-60 min

Porous double wrapped

0.5 Kg

0.15 Kg

Hollow simple wrapped

3.5 Kg

1 Kg

Solid or hollow double wrapped

1.5 Kg

0.5 Kg

Prion

134 0C

210 kPa

18 min

30-50 min

Porous unwrapped

0.1 Kg

0.3 Kg

Porous simple wrapped

0.75 Kg

0.2 Kg

Porous double wrapped

0.5 Kg

0.15 Kg

Hollow simple wrapped

3.5 Kg

1 Kg

Solid or hollow double wrapped

1.5 Kg

0.5 Kg

B&D test

134 0C

210 kPa

3.5 min

22-35 min

-

-

-

Helix test

134 0C

210 kPa

3.5 min

22-35 min

-

-

-

Vacuum test

-

-

-

18-20 min

-

-

-

Safety:

A cycle will not start unless the door is firmly closed.

An automated system with double hydraulic locking device prevents the door from opening while chamber is pressurized.

The safety valves prevent overpressure in the generator and in the chamber.

A safety thermostat prevents overheating in the chamber and in the generator.

An automatic safety lock prevents accidental opening of the door during the sterilisation. A power protector automatically cuts off power in case of short circuit or if power supply is not very stable.

The failure alarm indicates a cycle failure and provides an error code.

The door alarm indicates that the door is not properly closed.

The low water alarm indicates when the water tank is empty or too full.

Technical features:

Power supply: 220-240V; 50/60Hz; 10A

Chamber: 200 x 360 mm

Breaker: F16A / 400V

Nominal power: 2200VA

Sterilisation temperature: 121 0C / 1340C

Capacity of the distilled water tank: 2.5 L

Working temperature: 5 0C / 40 0C

Working relative humidity: Max. 80%, non condensing

Overall dimensions: 414 x 365 x 570 mm

Net weight: 51 Kg

Max. noise level: <70 dB

Atmospheric pressure: 76 / 106 kPa

Components:

Distilled water tank

LCD display

Control panel

Main power switch

Drain connector (distilled and used water tank)

USB port

Safety valve

Ventilation grid

Circuit breaker

Power cable

Rating plate

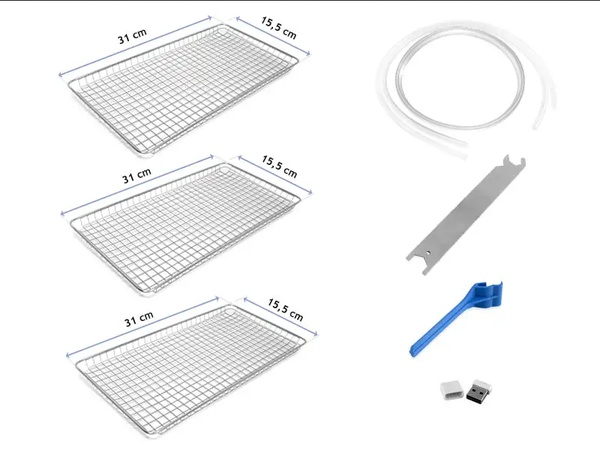

Accessories included:

Steriliser

USB

3 instrument trays

Tray rack

Tray holder

Door adjustment tool

2 draining hoses

Door gasket

User manual

Standards:

93/42/EEC Directive on Medical Devices.

97/23/EEC Directive on Pressure Equipment.

EN 13060 Small Steam Sterilisers.

EN 61326, EN 61000 Electromagnetic Compatibility.

EN 61010-1, UL 61010-1 Safety requirements.

EN 61010-2-040, IEC 61010-2-040 Specific requirements for steam sterilisers used for treatment of medical materials.

AUTOCLAVE - step by step:

Open the door, take the tools and accessories that are within the sterilisation chamber, remove the wrapper and clean them.

Connect the power cord to a suitable power source.

Connect the printer (optional. It is sold separately, ).

Switch on: The main switch is located on the right bottom area in the front panel.

Once activated, the LCD screen is on, where basic operation icons such as the position of the door, the water level, the sterilisation programme, date, time, etc. appear.

Fill tank with distilled water.

Remove the top lid and fill, if you hear a signal, it means that you exceeded the permitted level of water in the tank, please stop immediately and drain the amount of water necessary for the signal off.

Preparation of instruments:

Place instruments made of different materials in different trays, however take care to separate them before sterilisation.

If the instruments are not stainless steel, put some sterilisation paper between the tray and the instruments.

Do not allow direct contact between instruments of different materials.

Verify that all instruments are in correct position.

Place instruments such as lenses, containers, tubes, etc. inverted, so that water does not stagnate within them.

Do not overload the trays beyond their limit.

Do not overlap the trays on top of each other, or put them in direct contact with the wall of the sterilisation chamber.

Do not use metal clips or pins, this may impair the operation of the steriliser.

Wrap the instruments one by one. If you need to wrap several instruments together, make sure that they are made of the same material.

Seal the pouch with special adhesive tape for sterilisation or use a heat sealer.

Make sure that the pouch is properly positioned within the chamber on the trays (resting on the plastic part).

Choose the sterilisation programme.

Start the sterilisation cycle.

After selecting the sterilisation programme, insert instruments into the chamber on the trays, using the supplied plastic handle.

Once the instruments are placed within the chamber, close the door by turning the knob.

Caution: make sure to close the door, otherwise the steriliser displays an alarm and can not start or the programme stops during the cycle.

Start the sterilisation programme.

Press the start button, then the steriliser starts operating during approximately 30-75 minutes.

Sterilisation cycle finished.

After finishing the sterilisation cycle, the printer (not included*) will print the full report automatically and the data will be saved in the USB memory (.txt format).

After the pressure drops to zero, you can open the door and remove the instruments. The steriliser alerts by a beep once the sterilisation cycle is completed.

Caution: Use the supplied plastic handle for supporting trays when you take out the instruments.

IMPORTANT: Do not reuse used water.

Installation:

There must be at least 10 cm of free space around the steriliser, 25 cm at the top, and enough room to open the door.

The place where the steriliser is used must have proper ventilation.

The steriliser must be placed on a stable surface and at an appropriate height for handling.

Do not cover or block the lateral outlets or the outlet air grid of the condenser fan.

Do not place the steriliser near water sources.

Keep away from heat sources.

Example of printed report:

================================Programme: WRAPPED

Temperature: 134CPressure: 206.0 kPaDrying time: 08minSterilisation time: 4.0Min--------------------------------Time Temp. pressureStart 12:28:17 089.0CT1: 12:31:32 087.1C -075.0kPaT2: 12:33:43 110.2C 052.0kPaT3: 12:36:37 088.9C -080.0kPaT4: 12:39:20 114.7C 053.7kPaT5: 12:43:37 087.9C -080.0kPaT6: 12:50:40 134.8C 206.0kPaTS: 134.7C 209.5kPaMax. Temperature: 135.2CMin. Temperature: 134.3CMax. Pressure: 214.0kPaMin. Pressure: 204.9kPaT7: 12:54:39 134.4C 211.4kPaT8: 12:57:36 102.1C -060.0kPaT9: 12:59:54 098.2C -060.0kPaEnd 13:04:07 102.4C--------------------------------Cycle No .: 00017Result: successDate: 07/06/2014SN: E54723operator:================================

Learn more

Check availability

USD

1008.3

-

1118.3

USD

Minimum order: 50 pcs

Supply ability: 1000 pcs/per month

BVM MEDICAL LIMITED

Not verified supplier

United Kingdom

Shipping information

Calculate and complete your cargo transportation worldwide using Qoovee Logistics.

Guaranteed shipment on time and secure payment Calculate shipping from QooveeSimilar products

Quiver Medic

South Korea

Specify the price

USD

0

0

Lipo Lab PPC Solution non-surgical liposuction is a new generation lipolytic that destroys fat cells and removes them from the body. Thanks to a special technology, the particles of the active ingredients of the drug have a size of 50-70 microns (smaller than a cell): sodium deoxycholate envelops the membrane of fat cells, which are loosened under its influence, and phosphatidylcholine (PPC) turns them into an emulsion that is easily excreted from the body. Lipo Lab PPC Solution lipolytic is effective against cellulite, helps in the fight against local fat deposits. Gives a quick effect of lipolysis. Increases elasticity and turgor of the skin, preventing the appearance of wrinkles and sagging of the skin. Gives effective long-term results. Can be used to model the contours of the face and body. Active Ingredients: Phosphatidylcholine (PCC) highly purified, 99.8% pure (made in Germany) Highly purified sodium deoxycholate, 98% pure (made in Japan) Application: - Chin - Shoulders and forearms - Back and stomach - Side folds - Buttocks - Thighs - Knees. To order please send a private message. Worldwide shipping at competitive prices.

DaeHan Meditech Co. Ltd

Gunpo-si, South Korea

USD

6.0 - 6.5/pcs

AllCheck COVID-19 IgG/IgM

is an immunochromatographic test kit with virus antigens for the rapid and accurate determination of IgG and IgM antibodies against COVID-19 in human whole blood (finger capillary or venous), serum or plasma. Antibodies detected using this test indicate that the person had an immune response to COVID-19, regardless of whether the symptoms developed as a result of the infection or the infection was asymptomatic. Test result - 10 minutes. Additional equipment is not required. Box - 25 pcs. Price FOB Korea 6.0USD/pc

Specifications

•Testing time: 10 minutes

•Enough 1 drop of test sample : 10㎕

•Test sample : Whole blood (finger capillary or venous), serum, plasma

•Convenience and efficiency : No need for extra equipment

•“On place” testing : Fast and accurate diagnosis of contact persons and risk groups

•High sensitivity : Identification of asymptomatic infection

•Test accuracy : 95%

•Test sensitivity : 93,5%

•Test specificity : 98%

•Storage temperature : 1~30°C

•Shelf life : 12 months

DaeHan Meditech Co. Ltd

Gunpo-si, South Korea

USD

7.5 - 8.0/pcs

MolecuTech® Real-Time COVID-19 kit for performing reverse transcriptase - polymerase chain reaction (RT-PCR) in real time, designed for the qualitative determination of nucleic acid from SARS-CoV-2 in bio-samples (smear / sputum) taken from patients with suspected COVID-19. This multiplex set consists of an RdRP gene specific primer / probe for detecting SARS-CoV-2 and E gene specific primer / probes for detecting all coronaviruses and RNA isolated from respiratory tract samples. MolecuTech® Real-Time COVID-19 is used in the Republic of Korea with permission from the MFDS and complies with the applicable essential requirements of the IVD directive 98/79 / EC. Certificates: EN ISO 13485: 2016, GMP. Features • Dual target detection for RdRP and E genes • A special primer / probe mixture to increase its specificity • Rapid test results: 2 hours • Specificity: 100% • Sensitivity: 95% • Samples for analysis: sputum, tracheal aspirate (lower respiratory tract ); nasopharyngeal and oropharyngeal swabs (upper respiratory tract)

Farizze

Turkey

Specify the price

USD

0

0

Disposable Coverall (Nonwoven Spunbond ss).

25-30 gr.

unlaminated.

front 80 cm zipper for easy wearing and taking off.

It is air permeable, water repellent, flame retardant, particle proof, bacteria proof, light and soft.

You can use it in any area you want. It is generally used as overalls.

Production capacity over 10.000 pieces per week.

made in Turkey.

Farizze

Turkey

USD

1.15 - 2.0/pcs

20-25-30-40 gr. unlaminated. Front zip 80 cm for easy donning and doffing. It is breathable, water repellent, fire retardant, particle and bacteria resistant, lightweight and soft. You can use it anywhere you like. Usually used as workwear. Production capacity is over 12,000 pieces per week. Made in Turkey.

AE Group

Kazakhstan

USD

0.09 - 0.1/pcs

Vacuum tubes (vakutainer) with a clotting activator and gel allow you to obtain a larger volume of serum than in standard tubes, due to a clearer separation of the clot.

Applications: clinical chemistry, immunology, protein electrophoresis, serology, microbiology, toxicology.

AE Group

Kazakhstan

USD

0.05 - 0.09/pcs

The test tube is used to collect material and analyze biochemistry, serology, bacteriology, and blood group determination. Sterilized by gamma radiation. The design excludes the contact of the employee with the patient's blood and the patient's blood with the environment. To accelerate blood clotting, an activator of clot formation (SiO2-silicon dioxide, also called clot activator, clot-activator, AC, silica) is applied to the walls to accelerate blood coagulation, which ensures the separation of serum and clot for up to 48 hours without re-centrifugation. Volume 5 ml, 6 ml, 8 ml, 9 ml, Sizes 12 * 100mm - 5ml, 6ml, 16 * 100mm - 8ml, 9ml.

USD

168.34/pcs

168.34

DISINFECTANT CABINET

2.4 INCH TOUCH SCREEN

USED FOR NUMBER OF PEOPLE AND SETTINGS

SPRAY SETTING BETWEEN 1SN TO 10 SEC

LLC "KoFa"

Russia

USD

8.0 - 10.5/pcs

DuPont™ Tyvek® 500 Hooded Jumpsuit Expert.Material: TYVEK polyethylene - 100%, 41 g/m²Weight: less than 180g.Closure: zipperDesign features: 3-piece hood provides optimal fit and freedom of movement of the head. Elasticated hood, cuffs and hem, glued-in elastic waistband.Design allows for freedom of movement.Easy to grip with gloves, oversized zipper pull tab.Tyvek® material is made from high-density polyethylene fibers using fast twist technology for a superior fit. protective properties, durability and convenience. Tyvek® is a breathable material that is permeable to air and water vapor, but repels splashes of aqueous solutions and aerosols. A high degree of barrier protection against fine particles, viral and bacterial agents, fibers up to 1 micron in size, and at the same time extremely low linting of the material itself. Antistatic treatment. Silicone-free. Applications: medical, pharmaceutical, chemical, oil and gas, equipment repair, paint spraying, general cleaning and many others. Complies with TR CU 019/2011Color: white Size range: S, M, L, XL, XXL, XXXL

LLC "KoFa"

Russia

USD

1.03/pcs

1.03

Reusable lint-free cloth for clean rooms, laboratories, operating rooms, industries with increased requirements for cleanliness. • Used to remove excess sealant, mastic and other contaminants. • Due to the special structure of the knit, they have excellent absorbent properties and are able to capture dust particles. • Wipes do not contain silicone. • Convenient size and unique strength properties provide multiple use - at least 50 applications. • Maintain hostile environment for processing - solvents, acids, alcohols. • Sterilization is possible. (Autoclave, chemistry) Particularly strong and durable - technical cloth with overlaid edges. The standard size of 35x40 cm is convenient for any manipulations when cleaning or wiping equipment. Package options: 3 pcs. 5 pieces. 10 pieces. and more FORMULA FOR CALCULATION OF THE BENEFITS OF APPLICATION AND PURCHASE: 90r / 50 applications = 1rub 80 kopecks for 1 application!!!

Specify the price

USD

0

0

The LigaSure Impact™ device is lightweight and easy to use. It is designed to optimize performance in a wide range of specialties, including urology, colorectal and general surgery, and gynecology.

Suppliers in this category

All suppliers in the category

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message