Product description

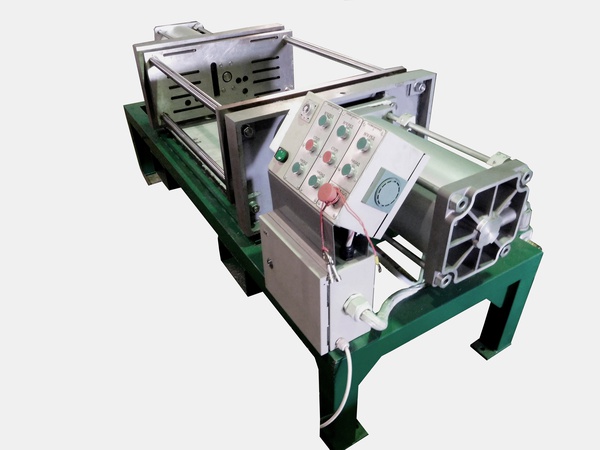

Designed for the implementation of the casting process and chill mold. Consists of: a base on which all installation mechanisms are mounted; two stationary plates interconnected by guide rods; two movable plates to which chill molds are attached; two pneumatic cylinders fixed on stationary plates and driving movable plates. The pneumatic cylinders are equipped with sensors to adjust the stroke length when changing chill molds; rod undermining mechanism; pneumatic equipment; electrical equipment with a control panel. Operation of the installation: when you press the "forward" button, the movable plates with installed chill molds move. Moreover, both pneumatic cylinders are controlled by one valve. In this case, the first plate that starts to move, which has less resistance to movement. When the half-die reaches the stop, the pressure begins to grow and the second plate moves until the halves of the die come into contact. The pressure rises to working pressure. Metal can be poured. After the metal is poured and the casting has cooled, the button "rod blowing" is pressed. After that, press the "back" button and the plates with the halves of the chill molds diverge.

Learn more

Check availability

Specify the price

0

0

USD

Minimum order: 1 pcs

Supply ability: 6 pcs/per month

ООО ПКФ ПРОТЕМ

Not verified supplier

Рыбинск, Russia

Shipping information

Calculate and complete your cargo transportation worldwide using Qoovee Logistics.

Guaranteed shipment on time and secure payment Calculate shipping from QooveeSimilar products

KUPERTEK LLC

Харьков, Ukraine

USD

417.0/pcs

417.0

Belt sander grinder KUPERTEK 3002 with vertical belt feed and 380 V connection

Specifications:

Overall dimensions: length 740-990 mm, width 370 mm, height 450 mm

Weight: 32 kg

Motor power: 1.1 kW

Number of revolutions: 2840 rpm

380 V connection

Belt width: 50 mm

Belt length: 1000 ... 1500 mm

Belt speed: 20 m / s

Drive roller diameter: 135mm

Table size: length 150 mm, width 250 mm

Working height: 290 mm

Tilt angle of the belt: 40 ° ... 110 °

Swivel mechanism - no

ООО ПКФ ПРОТЕМ

Рыбинск, Russia

Specify the price

USD

0

0

The single-position chill mold UKL-450 provides reliable opening and closing with pressing of two mold halves with a vertical split plane.

The UKL-450 provides the ability to quickly remove and install the stationary mold from the stationary plate of the machine.

ООО ПКФ ПРОТЕМ

Рыбинск, Russia

Specify the price

USD

0

0

Designed for the implementation of the casting process and chill mold. Consists of: a base on which all installation mechanisms are mounted; two stationary plates interconnected by guide rods; two movable plates to which chill molds are attached; two pneumatic cylinders fixed on stationary plates and driving movable plates. The pneumatic cylinders are equipped with sensors to adjust the stroke length when changing chill molds; rod undermining mechanism; pneumatic equipment; electrical equipment with a control panel. Operation of the installation: when you press the "forward" button, the movable plates with installed chill molds move. Moreover, both pneumatic cylinders are controlled by one valve. In this case, the first plate that starts to move, which has less resistance to movement. When the half-die reaches the stop, the pressure begins to grow and the second plate moves until the halves of the die come into contact. The pressure rises to working pressure. Metal can be poured. After the metal is poured and the casting has cooled, the button "rod blowing" is pressed. After that, press the "back" button and the plates with the halves of the chill molds diverge.

ООО ПКФ ПРОТЕМ

Рыбинск, Russia

Specify the price

USD

0

0

It is intended for obtaining solder rods by the method of continuous pulling upward of casting billets from copper melt and cutting them into dimensional cuttings. Consists of: pulling stand of two-roll type, operating in step-by-step mode from one drive with the possibility of individual pressing of each workpiece at two points; molds mounting brackets; carts for manually moving metal receivers; devices for cutting bars into measured lengths; common installation frame; machine control system, including cabinet and control panel. Smelting furnaces are not included in the scope of delivery.

ООО ТПК "ПромИнвест"

Russia

USD

125.34 - 1307.87/Ton

Мы являемся официальным дилером Бентогруппминиралс (Иджеванское месторождение, армения)

-Бентонит для буровых растворов

-Бентонит для металлургии

-Бентонит для литейного производства

-Бентонит для очистки воды

-Бентонит для виноделия

-Бентонит как добавка в корм для животных

-Наполнитель для кошачьего туалета

-Бентонит в качестве пищевой добавки

-Бентонит для строительства

-Бентонитовые маты

-Бентонит для бытовой химии

Поставляем по всему миру

ООО "ДОНЛИТПРОМ"

Russia

Specify the price

USD

0

0

ООО "ДОНЛИТПРОМ" donlitprom.ru Специализируется на литье алюминиевых изделий методом вакуум пленочной формовки на собственном оборудовании из алюминиевых сплавов АК9ч, АК9М2, АК12ч, АК12пч, АК12оч, АК12, ....

В перечень производимой нами продукции входят:

Различные корпуса, шкивы и т.д;

Промышленные и уличные фонари;

Лавочки, столы, скамейки, балясины, лестницы и др.;

Литые изделия из алюминия по индивидуальным проектам.

Компания сертифицирована по ИСО 9001-2008.

Наше предприятие обладает высококвалифицированным производственным персоналом. Благодаря техническому оснащению и современному парку оборудования мы осуществляем полный цикл производства от разработки и производство модельной оснастки до выпуска готовой продукции. Для производства изделий, применяется 3D-модель отливки, что повышает точность изготовления и последующую повторяемость.

ООО «Энерготех», г.Барнаул

Russia

USD

1013.6/pcs

1013.6

The trading and manufacturing company sells machines "PROFI-2R" with a manual drive through a gearbox, for the manufacture of artistic products from a profile pipe and other rolled metal products, using the "cold" forging method. Which in the future and in a certain combination are welded into fences, gates, grilles, canopies, furniture and much more.

In 2016, the machines of the PROFI series were modernized. This made it possible to apply a new technology for the manufacture of forging elements from a profile pipe, squeezed on four sides by a V or U-shaped groove and curled "along the edge" (diagonal), with a jam of the end "goose foot" without heating the workpiece. Forging products made by this method: "curl", "monogram", "volute", "ring", are multifaceted and look more attractive (see the photo on the site).

The PROFI-2R machine is easy to use. For inclusion in the production process, the machine operator will need no more than an hour.

The main advantages of the PROFI-2R machine are:

• a wide range of operations and equipment in the "basic configuration";

• absence of complex installation of additional devices, adjustment of rollers and guides for various operations;

• simplicity and convenience in work, as well as in maintenance;

• price availability of components and spare parts.

The PROFI-2R machine performs the following operations:

• operation - decorative squeezing of a profile pipe with a V groove;

• operation - "foot jam", rolling of the ends of a profile pipe of two options: in a plane or "goose foot";

• operation - "twisting a spiral" into elements: "curl", "currency", "monogram", "rings", torsion and making a "bump";

ООО «Энерготех», г.Барнаул

Russia

USD

1416.85/pcs

1416.85

Trade and production company sells machines "PROFI-2EM" with an electromechanical drive through a gearbox. The machine is designed for the manufacture of art products from a profile pipe and other rolled metal products using the "cold" forging method. Which in the future and in a certain combination are welded into fences, gates, grilles, canopies, furniture and much more. In 2016, the machines of the PROFI series were modernized. This made it possible to apply a new technology for the manufacture of forging elements from a profile pipe, squeezed on four sides by a V or U-shaped groove and curled "along the edge" (diagonal), with a jam of the end "goose foot" without heating the workpiece. Forging products made by this method: "curl", "monogram", "volute", "ring", are multifaceted and look more attractive (see the photo on the site). The PROFI-2EM machine is easy to use. For inclusion in the production process, the machine operator will need no more than an hour. The main advantages of the machine are: a large set of operations and equipment in the "basic configuration"; • absence of complex installation of additional devices, adjustment of rollers and guides for various operations; • simplicity and convenience in work, as well as in maintenance; • price availability of components and spare parts. The PROFI-2EM machine performs the following operations: • operation - decorative squeezing of a V or U shaped pipe with a groove; • operation - "foot jam", rolling of the ends of a profile pipe of two options: in a plane or "goose foot"; • operation - "twisting a spiral" into elements: "curl", "currency", "monogram", "rings", torsion and making a "bump"; Specifications: • overall dimensions, (length x width x height) 800x480x850 mm; • machine weight - 105 kg.

Suppliers in this category

All suppliers in the category

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message