Product description

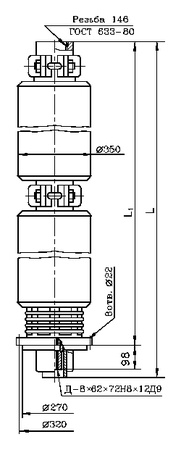

Submersible centrifugal pumping units ECPK, manufactured according to TU 3631-024-00162984-2014, are intended for injection into injection wells of industrial wastewater with a density of no more than 1400 kg / m3, with a temperature of up to 333K (60 ° C), hydrogen index ( pH) from 5.4 to 9, total mineralization - no more than 250 g / l, with the content of mechanical impurities up to 0.1 g / l. Climatic modification - U * and HL *. Pumps are used in the oil industry to maintain reservoir pressure in oil fields. Design: High technical and economic indicators and increased reliability of operation of units produced by the Molot-Mechanika Plant in comparison with similar units from other manufacturers is provided primarily due to design features: special bronze or stainless steel, and the fasteners are made of corrosion-resistant steel, which ensures durability of work in an aggressive environment. If necessary (as agreed with the customer), it is possible to select special grades of bronze, steel, rubber for the unit to operate in special conditions. -the unit uses graphite-fluoroplastic or rubber-metal radial bearings, depending on the properties of the pumped medium; - self-aligning segment thrust bearings (thrust bearings) made of graphite-fluoroplastic are used in the engine and in the pumping part, which increases the reliability of the unit; - the units use sealed water-filled electric motors. The mechanical seal installed on the rotor shaft eliminates the contact of an aggressive environment with the stator-rotor package and the winding, which significantly increases the service life of the electric motor; - engines for units operating in difficult conditions are designed with an additional power reserve in accordance with high mine requirements; -copper-filled rotor is made of type-setting of electrical steel, which ensures a decrease in magnetic losses, an improvement in starting characteristics and an increase in the efficiency of the engine; - a winding wire with reinforced insulation is used, which increases the reliability of the engine; - improved engine cooling circuit. In engines with a power of 250 kW and above, a forced circulation system is used. - when installing the unit in a well and a large-diameter well, a cooling jacket is provided to ensure a normal cooling mode of the engine. UETsPK standard size Q, m3 / day Q, m3 / h H, m N, kW (at 1000 kg / m3) N, kW (at 1200 kg / m3) Pump weight, kg D, mm L pump, mm U, V Weight unit, kg Unit length, mm 16-2000-160 2000 83.3 160 90 110 275 375 980 380 or 1150 or 2200 or 3000 or 6000 727 2440 16-2000-200 2000 83.3 200 90 110 310 375 1020 762 2480 16-2000-450 2000 83.3 450 190 220 900 375 1930 1993 4731 16-2000-900 2000 83.3 900 375 500 1734 375 3365 3490 6799 16-2000-1400 2000 83.3 1360 442 700 2584 375 4909 4404 8489 16-3000-160 3000 125 160 90 115 210 375 895 662 2355 16-3000-200 3000 125 200 110 132 265 375 1095 741 2615 16-3000-250 3000 125 250 150 180 320 375 1145 852 2805 16-3000- 500 3000 125 500 280 500 785 375 1905 2541 5339 16-3000-1000 3000 125 930 435 700 1526 375 3055

Learn more

Check availability

Specify the price

0

0

USD

Minimum order: 1 pcs

Supply ability: 100 pcs/per quarter

Hammer Factory

Not verified supplier

Russia

Shipping information

Calculate and complete your cargo transportation worldwide using Qoovee Logistics.

Guaranteed shipment on time and secure payment Calculate shipping from QooveeSimilar products

ООО Артмаш

Ukraine

Specify the price

USD

LLC Artmash offers an exact loading screw with a mixer of its own production. This is a new development of our factory, created especially for those who are not able to buy an accurate feed screw and mixer separately, or cannot place them in one room. Buying a screw + mixer you get the same performance and save 35 500 hryvnia. The product is designed for use in the production lines of feed pellets and fuel pellets. The auger is not afraid of debris entering the pellet raw materials, provides high line productivity up to 3 t / h. The screw model with engine speed control is equipped with a worm gear. The mixer allows you to prepare a homogeneous mixture (96%) of feed, dietary supplements, premix, vitamins. Mixing occurs within 6 minutes; continuous operation is possible. Unloading of processed raw materials is carried out at the end, which allows you to use a metered feed screw in the kit, after which it can be sent for granulation. The feed mixer is controlled by 1 operator. A horizontal mixer will help saturate the feed with useful additives, balance the diet of animals, and ensure the growth of healthy livestock and poultry. Video with reviews of our customers Characteristics of the auger of the exact loading with a mixer Voltage: 380 V Dimensions: H2800hSh750hD1600 mm Weight: 200 kg Productivity: up to 3000 kg / h Feed Auger Motor Power: 0.55 kW Mixer motor power: 2.2 kW Hopper volume: 0.6 cubic meters

ООО Артмаш

Ukraine

Specify the price

USD

The manufacturer of agricultural equipment LLC Artmash offers a horizontal feed mixer with two counter belt mixers. Allows you to prepare a homogeneous mixture (96%) of feed, dietary supplements, premix, vitamins. Mixing occurs within 6 minutes; continuous operation is possible. Unloading of processed raw materials is carried out at the end, which allows the use of a dosed feed screw in the kit, after which it can be sent for granulation. The feed mixer is controlled by 1 operator. A horizontal mixer will help saturate the feed with useful additives, balance the diet of animals, and ensure the growth of healthy livestock and poultry. Video with reviews of our customers Characteristics of the horizontal mixer for the production of animal feed: Motor: 4 kW; Hopper volume: 0.6 cubic meters; Productivity: 1 ton per hour; Weight: 280 kg. Dimensions: LxWxH 1702 * 750 * 1900 m.

ООО Артмаш

Ukraine

Specify the price

USD

LLC "Artmash" is a manufacturer of lines for the production of pellets from animal feed of any composition for Ukraine and 20 other countries. At the request of the client, we can offer equipment of different capacities, we provide the most reliable information about the possibility of granulation of a particular raw material as well as possible performance. The standard line includes: Accurate loading auger 380V, 1.1 kW, 1500 rpm. Granulator 380V, 22 kW, 1500 rpm. Pellet cooler with vibrating table 380V, 5.5 kW, Video with reviews of our customers Before painting and selling all our equipment is tested for defects and their subsequent elimination. All nodes are made in-house with an inspection of quality control. Parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment. Contact us and we will help you choose the equipment of the necessary power and performance.

ООО Артмаш

Ukraine

Specify the price

USD

0

0

LLC Artmash is a manufacturer of lines for the production of pellets from waste wood processing industries for Ukraine and 20 other countries. At the request of the client, we can offer equipment of different capacities, we provide the most reliable information about the possibility of granulation of a particular raw material as well as possible performance. The standard line includes: Accurate loading auger 380V, 1.1 kW, 1500 rpm. Granulator 380V, 22 kW, 1500 rpm. Pellet cooler with vibrating table 380V, 5.5 kW, Before painting and selling all our equipment is tested for defects and their subsequent elimination. All nodes are made in-house with an inspection of quality control. Parts that are subjected to heavy loads are made of alloy steels with subsequent heat treatment. Contact us and we will help you choose the equipment of the necessary power and performance. Video with reviews of our customers The main advantages of our equipment: the matrix (die) is made of steel 20X with subsequent cementation in a thermal furnace. The hardness of the surface layer of the metal and the walls of the hole 62 HRC (bearing hardness) is achieved, which provides wear resistance for years of operation of the granulator; rollers are made in the same way as the matrix; the mechanism used involute helical gear transmission. Compared to spur gears, helical gear achieves a significantly lower noise level of the product as well as greater transmission durability; low power consumption. The matrix in diameter of 160 mm can work with 4 kW engines. 380 V and 4 kW, 220 V; in order to avoid engine overload, we have provided a thermal relay, which will timely turn off the engine in case of overheating; each granulator is tested for defects and repaired before painting and selling. Worm Gear Precision Auger Features Voltage: 380 V; Engine power: 1.1 kW, 1500 rpm; Productivity: up to 300 kg / h; Hopper volume: 0.6 cubic meters; Granulator weight: 140 kg; Dimensions: D2800 * W750 * H1600 mm. Characteristics of the pellet mill for pellets 380 V, 22 kW Voltage: 380 V; Engine power: 22 kW, 1500 rpm; Productivity: 400-800 kg / h; Granule diameter: 2-8 mm. The diameter of the matrix: 280 mm; Granulator weight: 400 kg; Dimensions: D1300 * W500 * H1300 mm. Pellet Cooler Characteristics Voltage: 380 V; Engine power: 4.5 kW, 3000 rpm; Productivity: up to 1000 kg / hour; Hopper loading volume: 1 cubic meter; Granule diameter: 2-6 mm. Diameter of the matrix: 160 mm; Granulator weight: 550 kg; Dimensions: D4000 * W1100 * H2500 mm.

ООО Артмаш

Ukraine

Specify the price

USD

0

0

LLC Artmash is a manufacturer of lines for the production of pellets from waste sunflower and other crops for Ukraine and 20 other countries. At the client’s request, we can offer equipment of different capacities, we provide the most reliable information about the possibility of granulation of a particular raw material, as well as possible performance.

The standard line includes:

Accurate loading auger 380V, 1.1 kW, 1500 rpm.

Granulator 380V, 22 kW, 1500 rpm.

Pellet cooler with vibrating table 380V, 5.5 kW,

Before painting and selling all our equipment is tested for defects and their subsequent elimination. All nodes are made in-house with an inspection of quality control. Parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment.

Contact us and we will help you choose the equipment of the necessary power and performance.

Video with reviews of our customers

The main advantages of our equipment:

the matrix (die) is made of steel 20X with subsequent cementation in a thermal furnace. The hardness of the surface layer of the metal and the walls of the hole 62 HRC (bearing hardness) is achieved, which provides wear resistance for years of operation of the granulator;

rollers are made in the same way as the matrix;

the mechanism used involute helical gear transmission. Compared to spur gears, helical gear achieves a significantly lower noise level of the product as well as greater transmission durability;

low power consumption. The matrix in diameter of 160 mm can work with 4 kW engines. 380 V and 4 kW, 220 V;

in order to avoid engine overload, we have provided a thermal relay, which will timely turn off the engine in case of overheating;

each granulator is tested for defects and repaired before painting and selling.

Worm Gear Precision Auger Features

Voltage: 380 V;

Engine power: 1.1 kW, 1500 rpm;

Productivity: up to 300 kg / h;

Hopper volume: 0.6 cubic meters;

Granulator weight: 140 kg;

Dimensions: D2800 * W750 * H1600 mm.

Characteristics of a granulator for sunflower waste 380 V, 22 kW

Voltage: 380 V;

Engine power: 22 kW, 1500 rpm;

Productivity: 400-800 kg / h;

Granule diameter: 2-8 mm.

The diameter of the matrix: 280 mm;

Granulator weight: 400 kg;

Dimensions: D1300 * W500 * H1300 mm.

Pellet Cooler Characteristics

Voltage: 380 V;

Engine power: 4.5 kW, 3000 rpm;

Productivity: up to 1000 kg / hour;

Hopper loading volume: 1 cubic meter;

Granule diameter: 2-6 mm.

Diameter of the matrix: 160 mm;

Granulator weight: 550 kg;

Dimensions: D4000 * W1100 * H2500 mm.

ООО Артмаш

Ukraine

Specify the price

USD

The Artmash plant offers you a counter-current pellet cooler of its own production. The cooling column is designed to cool the granules coming from the granulator. The equipment is a countercurrent type cooling column. This means that air passes through the entire layer of granules, while simultaneously relieving them of excess moisture. Due to the passage of the granules through the cooling column, their temperature decreases from 70-90 degrees Celsius (at the exit of the granulator) to 15-20 degrees. Video with reviews of our customers Contents of delivery: cooling column with vibrating table; anti-dust blower fan; fan suction dust; control cabinet; scraper conveyor. The main parameters of the pellet cooler: Voltage: 380 V; Assembly Length: 4000 mm; Width: 1100 mm; Height: 2500 mm; Weight: 550 kg; Hopper loading volume: 1 cube m; Total engine power (4 pcs.): 3.85 kW; Productivity: up to 1000 kg / hour.

ООО Артмаш

Ukraine

Specify the price

USD

LLC Artmash offers you a feed granulator 380 V, 11 kW of its own production. Main advantages of our universal granulator: the matrix (die) is made of steel 20X with subsequent cementation in a thermal furnace. The hardness of the surface layer of the metal, as well as the walls of the hole 62 HRC (bearing hardness) is achieved, which ensures wear resistance for years of operation of the granulator; rollers are made in the same way as the matrix; the mechanism used involute helical gear transmission. Compared to spur gears, helical gear achieves a significantly lower noise level of the product, as well as greater transmission durability; in order to avoid engine overload, we have provided a thermal relay, which will timely turn off the engine in case of overheating; each granulator is tested for defects and repaired before painting and selling; All nodes are made in-house with a check of quality control. parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment. Video with reviews of our customers Characteristics of a feed granulator 380 V, 11 kW: Voltage: 380 V; Engine power: 11 kW, 1500 rpm; Productivity: grain feed 150-200 kg / h, straw 100 kg / h, sunflower husk 150-200 kg / h; Granule diameter: 2-8 mm; Diameter of the matrix: 200; Granulator weight: 230 kg; Dimensions: D1050 * W400 * H1000 mm.

ООО Артмаш

Ukraine

Specify the price

USD

0

0

LLC Artmash offers you a pellet granulator 380 V, 11 kW of its own production. Main advantages of our universal granulator: the matrix (die) is made of 18KhGT steel followed by cementation in a thermal furnace. The hardness of the surface layer of the metal and the walls of the hole 62 HRC (bearing hardness) is achieved, which provides wear resistance for years of operation of the granulator; rollers are made in the same way as the matrix; the mechanism used involute helical gear transmission. Compared to spur gears, helical gear achieves a significantly lower noise level of the product as well as greater transmission durability; in order to avoid engine overload, we have provided a thermal relay, which will timely turn off the engine in case of overheating; each granulator is tested for defects and repaired before painting and selling; All nodes are made in-house with a check of quality control. parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment. Video with reviews of our customers Characteristics of the pellet pellet 380 V, 11 kW: Voltage: 380 V; Engine power: 11 kW, 1500 rpm; Productivity: 200-300 kg / hour; Granule diameter: 6-8 mm; Diameter of the matrix: 200; Granulator weight: 230 kg; Dimensions: D1050 * W400 * H1000 mm.

ООО Артмаш

Ukraine

Specify the price

USD

0

0

The manufacturer of agricultural equipment LLC "Artmash" offers a hay shredder 380 V, 18.5 kW with or without a cyclone. The model is intended for industrial enterprises, characterized by increased productivity. Functions: processing of herbs (reeds, straw, alfalfa, hay); preparation of feed mixtures; bedding for animals; production of briquettes and fuel pellets. All nodes are made in-house with an inspection of quality control. Parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment. Video with reviews of our customers Hay shredder 380 V, 18.5 kW Main parameters: Voltage: 380 V; Engine power: 18.5 kW, 3000 rpm; Productivity: 800-1000 kg / h; Mesh diameter: 6 or 8 mm; Weight: 250 kg; Dimensions: H1450 * D1000 * W1050 mm.

ООО Артмаш

Ukraine

Specify the price

USD

0

0

The manufacturer of agricultural equipment LLC Artmash offers a grain chopper 380 V, 15 kV with a cyclone and vacuum cleaner. The ARTMASH 311-2 model is intended for industrial enterprises, it allows to process a large amount of feed per unit time. A vacuum cleaner for grain saves workers, and a cyclone ensures the purity of the finished product. All nodes are made in-house with an inspection of quality control. Parts that are subjected to heavy loads are made of alloy steels, followed by heat treatment. Video with reviews of our customers Grinder for grain 380 V, 15 kW with a cyclone and a vacuum cleaner "ARTMASH 311-2" Main parameters: Voltage: 380 V; Engine power: 15 kW, 3000 rpm; Productivity: 1000-1500 kg / h; Mesh diameter: 4 or 6 mm; Weight: 180 kg; Dimensions: V2200 * D2000 * W1500 mm.

Farizze

Turkey

Specify the price

USD

0

0

Disposable Coverall (Nonwoven Spunbond ss).

25-30 gr.

unlaminated.

front 80 cm zipper for easy wearing and taking off.

It is air permeable, water repellent, flame retardant, particle proof, bacteria proof, light and soft.

You can use it in any area you want. It is generally used as overalls.

Production capacity over 10.000 pieces per week.

made in Turkey.

Farizze

Turkey

USD

1.15 - 2.0/pcs

20-25-30-40 gr. unlaminated. Front zip 80 cm for easy donning and doffing. It is breathable, water repellent, fire retardant, particle and bacteria resistant, lightweight and soft. You can use it anywhere you like. Usually used as workwear. Production capacity is over 12,000 pieces per week. Made in Turkey.

Suppliers in this category

All suppliers in the category

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message